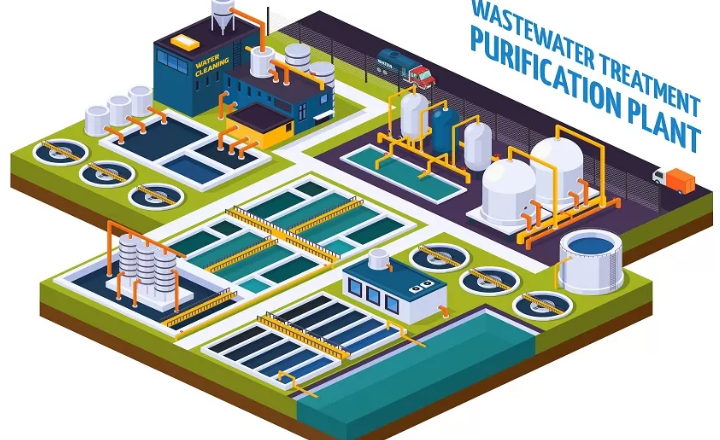

Designing an efficient wastewater treatment plant involves balancing capacity, energy use, and regulatory compliance through a multi-stage process. Key principles focus on preliminary screening, biological treatment, and advanced disinfection to achieve high pollutant removal rates. Modern designs prioritize modularity and automation for scalability and cost savings.

Design an Efficient Wastewater Treatment Plant: Importance

1. Wastewater Characterization

Accurate wastewater characterization is the first and most critical design step. Influent is analyzed for:

- Biochemical Oxygen Demand (BOD)

- Chemical Oxygen Demand (COD)

- Total Suspended Solids (TSS)

- Nutrients (nitrogen and phosphorus)

- Pathogens

- Emerging contaminants such as pharmaceuticals and pesticides

In agricultural regions of Punjab, wastewater flow and strength vary seasonally due to irrigation runoff and rainfall. To manage these fluctuations, equalization tanks are incorporated to stabilize flow and pollutant loading. Pilot studies are conducted to validate treatment efficiency and confirm design parameters before full-scale construction.

Optimal Treatment Technologies

Advanced wastewater recycling plants use hybrid treatment systems to achieve near-complete pollutant removal.

Main Treatment Train:

- Primary Clarification

Removes large solids and reduces organic load. - Membrane Bioreactor (MBR)

Combines biological treatment with membrane filtration, achieving high BOD, COD, and nutrient removal in a compact footprint. - Ultrafiltration (UF)

Removes fine particles, bacteria, and remaining suspended solids. - Reverse Osmosis (RO)

Produces high-quality water suitable for reuse by removing salts, dissolved solids, and trace contaminants. - UV/Ozone Polishing

Final disinfection step ensuring pathogen-free reuse-quality effluent.

For industries requiring maximum recovery, Zero Liquid Discharge (ZLD) systems are adopted. These systems minimize brine disposal using evaporators and crystallizers, achieving 95% or higher water recovery. Additionally, Membrane Aerated Biofilm Reactors (MABR) significantly reduce aeration energy consumption by up to 50%.

Compact and Modular Plant Layout

Efficient layout design reduces both capital and operational costs. Modern plants use:

- Modular, skid-mounted units for easy transportation and phased expansion

- Gravity-flow piping between treatment stages to minimize pumping energy

- Centrally located brine concentrators for ZLD systems

Digital twin technology is increasingly used to optimize hydraulic performance and process control. Well-designed plants consistently achieve:

- Turbidity < 1 NTU

- Total nitrogen < 1 mg/L

This ensures compliance with reuse standards and stable long-term operation.

Energy and Cost Efficiency

Energy optimization is vital due to high operational costs. Sustainable wastewater recycling plants integrate:

- Energy Recovery Devices (ERDs) in RO systems (up to 60% energy recovery)

- Solar-powered blowers and pumps

- Anaerobic digesters produce biogas from sludge for electricity and heat

Prefabricated modular construction can reduce capital expenditure by 20–30%, while automation and smart controls significantly lower operating costs. Most well-designed plants achieve return on investment (ROI) within 3–5 years. Lifecycle cost analysis ensures durability and performance over a 20+ year design life.

Reuse Applications and Monitoring

Treated wastewater is tailored to specific reuse applications:

- Agricultural irrigation (low sodium and pathogen-free)

- Industrial cooling towers (low scaling and corrosion potential)

- Non-potable domestic uses such as toilet flushing and landscaping

Continuous monitoring is essential for safety and reliability. IoT-based sensors measure flow, turbidity, nutrients, and conductivity in real time. AI-driven alerts notify operators of deviations, ensuring rapid corrective action. Sludge is further treated and reused as fertilizer, completing a circular economy loop.

Key Considerations for Effectively Designing a Water Treatment Plant

Designing an effective water treatment plant requires careful planning to ensure reliable purification of raw water for potable or industrial use. Key considerations span site factors, process efficiency, regulatory compliance, and long-term operability. These principles overlap with wastewater designs but emphasize source water quality and disinfection for safety.

Site and Capacity Planning

Site selection plays a critical role in plant performance and cost. An ideal location is close to the raw water source (river, lake, reservoir, or groundwater well) to reduce pumping energy and transmission losses. The site should have:

- Stable soil conditions

- Low flood risk

- Sufficient space for future expansion

Plant capacity is determined using population growth forecasts, average daily demand, and peak flow conditions. Designers also include redundancy, ensuring that if one treatment unit is offline for maintenance, the plant can still meet demand. Utilizing local topography for gravity flow further reduces operational energy costs.

Raw Water Analysis

Raw water quality directly influences treatment process selection. Engineers analyze parameters such as:

- Turbidity

- Pathogens (bacteria, viruses, protozoa)

- Organic matter

- Heavy metals and chemical contaminants

Seasonal variations—such as higher turbidity during monsoon or rainy periods—must be considered. Based on these results, appropriate chemical dosing and treatment stages are selected. Pilot testing is often conducted to verify process effectiveness before full-scale construction.

Main Water Treatment Processes

A conventional water treatment plant typically includes the following stages:

a) Intake and Screening

Raw water is collected and passed through screens to remove large debris like leaves, sticks, and plastics.

b) Coagulation and Flocculation

Chemicals (e.g., alum or ferric salts) are added to destabilize fine particles. Gentle mixing allows particles to form larger flocs.

c) Sedimentation (Clarification)

Flocs settle under gravity in sedimentation tanks, removing most suspended solids.

d) Filtration

Water passes through sand, gravel, or membrane filters to remove remaining fine particles and microorganisms.

e) Disinfection

Disinfection ensures pathogen-free water. Common methods include:

- Chlorination

- Ultraviolet (UV) radiation

- Ozonation

A residual disinfectant (usually chlorine) is maintained in distribution systems.

f) Storage and Distribution

Treated water is stored in clear water tanks and supplied to consumers through pipelines.

Process and Layout Design

Efficient layout design improves operability and maintenance. Straight-line hydraulic flow reduces head loss and energy use. Modular treatment trains allow individual units to be isolated without shutting down the entire plant. Baffles in clarifiers improve detention time, while BIM and CAD tools help simulate flows and avoid design clashes.

Equipment Selection and Safety Standards

Equipment must comply with recognized standards such as AWWA and ASME. Key components include:

- High-efficiency pumps

- Certified pressure vessels and valves

- Accurate chemical dosing systems

- Online sensors for pH, turbidity, and residual chlorine

Automation and fail-safe systems improve reliability and operator safety. Low-maintenance technologies such as membrane filtration or advanced oxidation are increasingly preferred.

Energy and Environmental Considerations

Energy optimization reduces long-term operating costs. Measures include:

- Energy-efficient pumps and motors

- Variable frequency drives (VFDs)

- Solar or renewable energy integration

Environmental aspects such as noise control, visual aesthetics, sludge handling, and spill containment help ensure community acceptance. Lifecycle cost analysis evaluates economic performance over a design life of 20–30 years.

How Can Technology Assist You in Designing an Efficient Water Treatment Plant?

Designing an efficient water treatment plant (WTP) is a complex and collaborative engineering task that requires accuracy, coordination, and continuous optimization.

Modern technologies such as Computer-Aided Design (CAD), Building Information Modeling (BIM), automation tools, and simulation software play a vital role in improving design quality, reducing costs, and ensuring regulatory compliance. These tools help engineers visualize, analyze, and refine plant designs before construction, resulting in safer, more efficient, and sustainable water treatment systems.

Role of Technology in Water Treatment Plant Design

- Detailed Design Creation

CAD software such as AutoCAD, Plant 3D, PDMS, and Revit allows designers to create accurate 2D and 3D drawings of water treatment plant components. These include pumps, valves, tanks, pipelines, reactors, clarifiers, and structural elements.

Detailed drawings help identify design flaws, incorrect alignments, or space constraints at an early stage. This early detection minimizes construction errors, reduces rework, and ensures smooth plant operation after commissioning.

- Accurate Visualization and Simulation

BIM and CAD tools provide 3D visualization of the entire water treatment plant. Designers can clearly see how different units interact spatially and functionally.

Simulation tools allow engineers to:

- Analyze hydraulic flow behavior

- Predict treatment efficiency

- Identify clashes between piping, equipment, and structures

This improves plant efficiency, safety, and functionality while reducing unexpected site issues.

- Better Design Iterations

Technology enables designers to test multiple design alternatives quickly. Parameters such as pipe diameters, tank sizes, materials, and flow paths can be adjusted digitally.

Using simulation results, engineers evaluate performance under different operating conditions and refine designs accordingly. This iterative process leads to optimized layouts, reduced energy consumption, and improved treatment efficiency.

- Seamless Collaboration

CAD and BIM platforms support multi-user collaboration, allowing engineers, architects, environmental experts, and stakeholders to work simultaneously on the same model.

Real-time updates, shared data, and centralized models improve coordination, reduce miscommunication, and ensure that all disciplines remain aligned throughout the project lifecycle.

- Detailed Documentation and Drawing Generation

CAD software automates the production of:

- Layout drawings

- Construction plans

- Equipment schedules

- Bills of quantities

This ensures consistency, accuracy, and faster documentation while reducing manual drafting errors.

- Hassle-Free Integration with Other Software

Modern CAD and BIM tools integrate easily with:

- GIS (Geographic Information Systems) for site analysis

- Hydraulic and process simulation software

- Cost estimation and scheduling tools

This interoperability improves data sharing and supports informed decision-making across all design stages.

Best Practices for Efficient WTP Design

Designing an efficient wastewater treatment plant (WTP) involves optimizing layout, processes, and technology to minimize energy use, costs, and environmental impact while meeting regulatory standards. Key principles draw from site assessment, modular design, and advanced automation. Best practices ensure scalability and reliability for varying wastewater volumes.

Choose the Right Software:

Selecting appropriate software is crucial. It should be compatible with existing systems, user-friendly, cost-effective, and capable of handling complex WTP designs. Popular tools include AutoCAD Plant 3D, Revit MEP, and Bentley WaterGEMS.

Expert consultation ensures the right tool selection for project-specific needs.

Follow Design Standards and Guidelines

Adhering to national and international standards ensures safety, reliability, and compliance. These guidelines help avoid design conflicts, technical errors, and regulatory violations while improving design quality.

Model in BIM

BIM provides a realistic, data-rich 3D model of the water treatment plant. It allows designers to:

- Detect clashes

- Optimize layouts

- Improve coordination

- Communicate effectively with stakeholders

BIM enhances accuracy and reduces construction risks.

Incorporate Automation and Simulation

Automation tools allow designers to update models quickly using predefined rules. Simulation tools test plant performance under varying flow rates, loads, and emergency scenarios.

This ensures feasibility, efficiency, and operational reliability of the plant design.

Partner with Experts

WTP design involves frequent revisions. Partnering with experienced CAD and BIM professionals ensures consistent modeling, accurate documentation, and smooth coordination, leading to optimized and error-free designs.

Design Calculations

Accurate calculations are essential for plant performance:

- Flow rate analysis determines treatment capacity

- Tank dimensions ensure proper storage and processing

- Retention time guarantees effective treatment

- Loading rates control organic and hydraulic stress

- Aeration requirements support biological processes

Technology automates and validates these calculations efficiently.

Components and Equipment

Major components include:

- Pumps and blowers

- Tanks and reactors

- Filtration units

- Sensors and monitoring devices

Digital models help in selecting, sizing, and placing equipment accurately.

Process Control and Automation

Advanced automation improves reliability and efficiency:

- SCADA systems for centralized control

- IoT-based monitoring for real-time data

- Real-time quality assessment for immediate corrective action

Automation reduces manual intervention and operational risks.

Cost Estimation

Technology supports accurate cost planning by estimating:

- Capital cost (construction and equipment)

- Operational cost (energy, chemicals, labor)

- Maintenance cost (repairs and replacements)

Early cost analysis helps optimize budgets and investment decisions.

Environmental and Economic Benefits

Efficient WTP design offers:

- Reduced freshwater consumption

- Lower wastewater discharge

- Cost savings for industries and communities

- Improved environmental protection

Water reuse supports sustainable development.

Challenges and Limitations

Despite advantages, challenges include:

- High initial installation cost

- Maintenance complexity

- Requirement of skilled operators

Proper training and planning help overcome these limitations.

Safety Considerations

Safety is critical in WTP design:

- Proper chemical handling systems

- Emergency shutdown mechanisms

- Worker protection and safety equipment

Technology enhances safety monitoring and compliance.

Conclusion

Technology plays a crucial role in designing efficient water and wastewater treatment plants. CAD, BIM, automation, and simulation tools improve design accuracy, collaboration, cost efficiency, and sustainability. Wastewater recycling plant design, in particular, helps conserve freshwater, reduce pollution, and provide reusable water for agriculture, industry, and communities, making it a sustainable and economical solution for future water management.