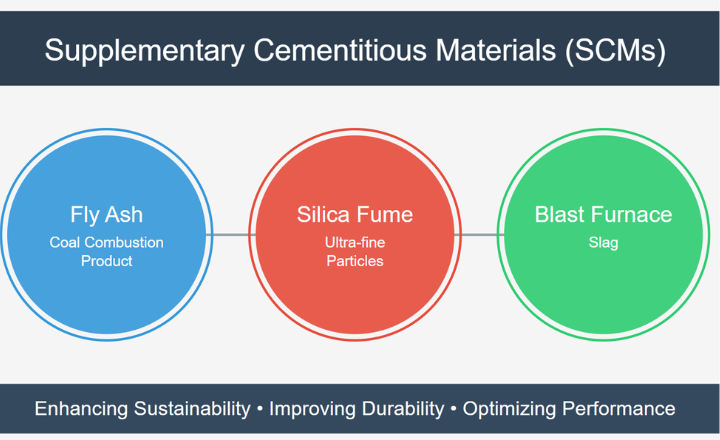

Supplementary Cementitious Materials (SCMs) are revolutionizing the way we think about construction and sustainability in the cement industry. By incorporating materials such as fly ash, slag, and silica fume, we can enhance the strength and durability of concrete while simultaneously reducing its carbon footprint. This ecological shift not only addresses the challenges posed by traditional cement production but also promotes the effective reuse of industrial by-products

Cement production accounts for approximately 8% of global carbon dioxide emissions, primarily due to the decomposition of limestone and the high-temperature processes used in clinker production. Moreover, the extraction of raw materials, such as limestone and clay, contributes to habitat destruction and resource depletion. Alternative Supplementary Cementitious Materials (ASCMs) are emerging as critical players in the quest for sustainable construction practices. These innovative materials, such as volcanic ash, glass powders, and natural zeolites, not only enhance the properties of concrete but also reduce its carbon footprint. Integrating ASCMs can improve durability, workability, and resistance to chemical attacks, making concrete structures more resilient over time

Common Types of SCMs

Cementitious materials (SCMs) play a pivotal role in the construction industry, enhancing the performance and sustainability of concrete. Among the most common types, fly ash stands out for its pozzolanic properties, allowing for improved workability and durability in concrete mixes.

Another need SCM is slag, which is derived from iron production. When incorporated into concrete, it significantly boosts resistance to aggressive environmental conditions, extending the lifespan of structures. Additionally, silica fume, a byproduct of silicon metal manufacturing, enhances concrete’s strength and permeability when added to mixtures.

Fly Ash

- Spherical particles

- Coal combustion product

- Reduces water demand

- Source: By-product of coal combustion in power plants.

- Composition: Rich in silica, alumina, and iron oxides.

- Benefits:

- Improves workability and reduces water demand.

- Increases long-term strength and durability.

- Reduces the heat of hydration, minimizing thermal cracking in mass concrete.

- Applications: Widely used in pavements, structural concrete, and mass concrete works.

- Challenges: Availability of high-quality fly ash is reducing due to declining coal usage.

Silica Fume

- Ultra-fine particles

- High reactivity

- Increases strength

- Source: By-product of silicon and ferrosilicon alloy production.

- Composition: Ultra-fine particles rich in amorphous silica.

- Benefits:

- Enhances high early strength due to accelerated hydration.

- Improves impermeability, reducing chloride penetration and corrosion risk.

- Adds resistance to chemical attacks like sulfates.

- Applications: Ideal for high-strength concrete in bridges, marine structures, and industrial floors.

- Challenges: Expensive and requires careful mix proportioning.

Blast Furnace Slag (BFS)

- Industrial byproduct

- Improves durability

- Reduces heat

- Source: By-product of iron production in blast furnaces.

- Composition: Contains calcium, silica, and alumina.

- Benefits:

- Provides latent hydraulic activity, improving strength over time.

- Reduces heat of hydration and enhances sulfate resistance.

- Lowers carbon footprint by reducing reliance on clinker.

- Applications: Commonly used in blended cements, precast concrete, and marine structures.

- Challenges: Requires energy for processing and grinding.

Natural Pozzolans

- Volcanic origin

- Sustainable option

- Cost-effective

- Source: Natural pozzolans, derived from volcanic ash, clay, or siliceous materials, offer a remarkable blend of ancient wisdom and modern innovation in construction.

- Composition: the primarily consists of reactive silica and alumina, which, when mixed with lime, create a strong bond that enhances the durability of concrete. Unlike conventional additives, natural pozzolans not only improve strength but also contribute to the sustainability of building materials by reducing the carbon footprint associated with cement production

- Benefits of natural pozzolans extend beyond mere structural integrity. They enhance workability and reduce permeability in concrete, which can significantly improve its longevity against environmental stresses.

- Application: for instance, variations in raw material quality can affect consistency in performance.

- Challenges: As the construction industry pushes for greener alternatives, embracing natural pozzolans could redefine standards for sustainable practices, promoting both aesthetic and environmental excellence.

Alternative Supplementary Cementitious Materials (ASCMs)

Alternative Supplementary Cementitious Materials (ASCMs) are industrial by-products or non-conventional pozzolanic materials that offer sustainable alternatives to traditional SCMs. They address challenges related to availability, cost, and performance while promoting environmentally responsible concrete production. Below is a detailed overview of key ASCMs:

Steel Slag

Types:

- Electric Arc Furnace (EAF)

- Basic Oxygen Furnace (BOF)

- Ladle Slags

Applications:

- Substitute for aggregates in asphalt and concrete.

- Used in low-strength concrete, backfill materials, and clinker production.

Benefits:

- Sustainability: Reduces natural material consumption and lowers CO₂ emissions in cement production.

- Resource Conservation: Decreases reliance on quarrying and mining of natural aggregates.

Challenges:

- Composition Variability: Inconsistent properties can affect concrete performance.

- Environmental Concerns: Potential for heavy metal leaching requires careful monitoringSugarcane Bagasse Ash (SCBA)

Sugarcane Bagasse Ash (SCBA)

Source:

- By-product of sugarcane milling and cogeneration boilers in the sugar industry.

Applications:

- Replacement for cement in low to moderate-strength concrete.

- Ideal for sustainable concrete production in sugarcane-growing regions.

Benefits:

- Waste Reduction: Utilizes industrial by-products, addressing disposal challenges.

- Enhanced Reactivity: Improves pozzolanic properties, boosting concrete strength and durability.

- Environmental Impact: Reduces carbon emissions by partially replacing cement.

Challenges:

- Quality Variation: Combustion conditions influence effectiveness as an SCM.

- Chemical Composition: Inconsistencies may necessitate mix design adjustments.

Waste Glass Powder (GLP)

Source:

- Recycled glass containers, construction glass, and other glass products.

Applications:

- Enhances chloride ion resistance, mitigating steel reinforcement corrosion.

- Reduces drying shrinkage, improving concrete durability.

- It can serve as an SCM or aggregate replacement in concrete.

Benefits:

- Waste Minimization: Diverts glass waste from landfills, promoting recycling.

- Energy Efficiency: Lowers energy demand for producing new glass.

- Sustainability: Provides a practical use for recycled glass in construction.

Challenges:

- Contamination Risks: Impurities and mixed glass types may affect concrete quality.

- Composition Variability: Different glass colors and types may require additional sorting for consistent performance.

Benefits of Using Supplementary Cementitious Materials (SCMs)

Supplementary Cementitious Materials (SCMs) and Alternative Supplementary Cementitious Materials (ASCMs) provide numerous advantages during both the fresh and hardened stages of concrete, as well as contributing positively to environmental sustainability. The benefits are outlined below:

Fresh Concrete

- Improves Workability:

SCMs and ASCMs enhance the workability of fresh concrete, making it easier to mix, place, and finish. They reduce water demand, allowing for a more workable mix without compromising strength. - Reduces Segregation:

These materials improve the cohesiveness of concrete, reducing the risk of segregation and ensuring a uniform distribution of cement, aggregates, and water throughout the mix. - Enhances Cohesiveness:

Fine particles in materials like silica fume or fly ash help bind the mix, improving cohesion. This leads to easier handling, placing, and finishing of concrete. - Economic and Environmental Benefits:

By reducing the amount of Portland cement needed, SCMs and ASCMs lower material costs. They also promote sustainability by repurposing industrial by-products, minimizing waste and resource consumption.

Hardened Concrete

- Increases Durability:

SCMs and ASCMs enhance concrete’s resistance to chemical attacks (e.g., sulfates or acids), making it suitable for harsh environments like marine structures and wastewater treatment plants. - Increases Strength:

Materials such as silica fume and fly ash contribute to long-term strength gains through ongoing pozzolanic reactions. This results in higher compressive strength and improved overall performance over time. - Resistance to Cracking:

By reducing the heat of hydration, SCMs and ASCMs lower the risk of thermal cracking in mass concrete. Their effect on the concrete microstructure also reduces shrinkage cracking, enhancing structural integrity. - Reduces Chloride Penetration:

The use of SCMs and ASCMs improves concrete impermeability, protecting embedded steel reinforcement from chloride-induced corrosion. This is particularly beneficial for structures exposed to de-icing salts or seawater. - Enhances Chemical Resistance:

These materials improve the chemical resistance of concrete, making it more durable against aggressive agents like sulfates that can degrade conventional concrete over time.

Environmental Impact

- Lowers Carbon Emissions:

Replacing a portion of Portland cement with SCMs or ASCMs reduces the demand for clinker, the most energy-intensive part of cement production. This directly lowers carbon emissions and helps mitigate the concrete industry’s environmental impact. - Encourages Recycling of Industrial Waste:

Many SCMs and ASCMs are derived from industrial by-products like fly ash, steel slag, and waste glass. Their use reduces landfill waste, supports recycling, and promotes a circular economy where materials are reused rather than discarded.

Structural Performance

- Enhanced Flexural Strength:

SCMs like silica fume and slag improve concrete’s ability to resist bending forces, making it suitable for beams and slabs subjected to heavy loads. - Improved Bond with Reinforcement:

SCMs refine the microstructure around steel bars, enhancing the bond between concrete and reinforcement, which increases structural integrity. - Reduced Shrinkage:

By optimizing the concrete mix, SCMs minimize drying shrinkage, reducing the risk of cracks and deformation over time.

Economic Efficiency

- Cost-Effective Mix Design:

Substituting a portion of cement with SCMs lowers the overall cost of concrete production, especially where SCMs are locally available. - Lower Maintenance Costs:

Enhanced durability and resistance to environmental damage reduce the need for frequent repairs, lowering the life-cycle cost of structures. - Optimized Resource Utilization:

Using SCMs reduces the need for raw materials like limestone and aggregates, promoting efficient use of resources.

Construction Efficiency

- Better Performance in Hot Weather:

SCMs reduce the heat of hydration, preventing rapid setting and improving concrete workability in hot climates. - Compatibility with Modern Techniques:

SCMs are ideal for advanced construction methods like self-consolidating concrete (SCC) and 3D-printed concrete. - Improved Finish Quality:

Fine particles in SCMs lead to smoother surface finishes, reducing the need for additional treatments or corrections.

Challenges of Using Supplementary Cementitious Materials (SCMs)

Despite the many benefits, the use of Supplementary Cementitious Materials (SCMs) and Alternative Supplementary Cementitious Materials (ASCMs) presents certain challenges that need to be addressed to maximize their potential. Below are the key challenges:

Variability in ASCM Quality and Composition

Variability in the quality and composition of Supplementary Cementitious Materials (SCMs) can significantly influence the performance of concrete. Factors such as the source of raw materials, production methods, and storage conditions can all contribute to discrepancies in the chemical and physical properties of SCMs. For instance, fly ash sourced from different coal types or regions may exhibit varied pozzolanic activity, affecting the hydration process and ultimately, the durability of concrete mixes. This raises critical questions about standardization and quality control, highlighting the need for stringent testing protocols to ensure consistency in performance.

Differences in particle size, mineralogy, and the presence of impurities can lead to unexpected variances in workability and setting times. The evolving landscape of SCMs offers a fertile ground for research and development, promising advances that could revolutionize the concrete industry.

Need for Long-Term Performance Studies

Long-term performance studies are critical for understanding the durability and resilience of constructions using Supplementary Cementitious Materials (SCMs). While short-term tests provide initial insights into the material properties, they often overlook the intricate behaviors that emerge over extended periods. Factors like environmental exposure, load-bearing conditions, and chemical interactions can significantly influence how SCMs perform, ultimately affecting the lifespan of structures.

Moreover, the use of SCMs can lead to unexpected benefits, such as enhanced resistance to chloride penetration and reduced alkali-silica reactivity. By conducting long-term performance studies, researchers can gather valuable data that not only validates the efficacy of SCMs in various environments but also guides future innovations in concrete technology. Understanding these long-term effects will empower engineers and architects to make informed decisions, ensuring safer, more sustainable structures that stand the test of time.

Importance of Technology for Waste Classification and Recycling

Incorporating technology into waste classification and recycling processes holds transformative potential for sustainable practices. Advanced sorting technologies, such as AI-driven image recognition and robotics, streamline the identification of materials, ensuring that valuable resources aren’t lost in general waste. This precision is critical, especially when it comes to integrating Supplementary Cementitious Materials (SCMs) into construction. By recovering these materials effectively, we not only reduce landfill waste but also create new avenues for recycling concrete, ultimately promoting a circular economy.

Moreover, the data analytics derived from technology can enhance decision-making in waste management. By analyzing waste streams, companies can identify trends and optimize recycling efforts, leading to greater efficiency. This not only reduces environmental impact but also encourages the construction industry to be more responsible by utilizing SCMs that enhance concrete durability and lower carbon emissions. Embracing technology in waste classification is not just an operational upgrade; it’s a commitment to innovation that fuels growth while preserving our planet’s resources.

Conclusion

In conclusion, Supplementary Cementitious Materials (SCMs) play a pivotal role in enhancing concrete performance and sustainability. By integrating materials such as fly ash, slag, and silica fume, we can significantly reduce the carbon footprint of construction projects while improving durability and workability. As the industry shifts towards greener practices, the use of SCMs not only aligns with environmental goals but also meets the demands of modern engineering.

Supplementary Cementitious Materials (SCMs) and Alternative Supplementary Cementitious Materials (ASCMs) are pivotal in advancing the sustainability of modern concrete. By reducing the reliance on traditional Portland cement, these materials contribute significantly to enhancing concrete’s properties and minimizing the environmental footprint of construction. SCMs like fly ash, silica fume, and blast furnace slag, along with emerging ASCMs such as steel slag and sugarcane bagasse ash, offer diverse benefits, including improved durability, strength, and resistance to aggressive environmental conditions.