Introduction

Wind Turbine design is the process of defining the form and configuration of a wind turbine to efficiently capture and convert wind energy into electrical power, considering factors such as aerodynamics, structural strength, power control, and environmental conditions. This involves optimizing components like blades, hub, nacelle, and tower to maximize performance, reliability, and longevity while managing loads and variability of the wind resource.

A small Wind Turbine in electric system will work for you if:

- There is enough wind where you live

- Tall towers are allowed in your neighborhood or rural area (or you live in flat terrain with no tall obstacles nearby)

- You have enough space

- You can determine how much electricity you need or want to produce

- You can interconnect with your utility service provider (assuming you have a grid-connection application)

- It works for you economically.

Small wind electric systems can contribute to our nation’s energy needs. This guide will provide you with basic information about small wind electric systems to help you decide if wind energy will work for you.

Why Should I Choose Wind?

Wind energy systems can be one of the most cost-effective home-based renewable energy systems. Depending on your wind resource, a small wind energy system can lower your electricity bill slightly or up to 100%, help you avoid the high costs of extending utility power lines to remote locations, and sometimes can provide DC or off-grid power. In addition, wind energy is local energy.

How Do Wind Turbines Work?

Wind is created by the unequal heating of the Earth’s surface by the sun. Wind turbines convert the kinetic energy in wind into mechanical power that runs a generator to produce electricity. Today’s turbines are versatile modular sources of electricity.Their blades are aerodynamically designed to capture the maximum energy from the wind.The wind turns the blades, which spin a shaft connected to a generator or the generator’s rotor, which makes electricity.

Is Wind Energy Practical for Me?

A small wind energy system can provide you with a practical and economical source of electricity if:

- Your property has a good wind resource.[7]

- Your home or business is located on at least 1 acre of land.

- Your local zoning codes or covenants allow wind turbines.

- You can determine how much electricity you need or want to produce.

- It works for you economically (you may be eligible for state/utility or federal incentives).

- You’re comfortable with long-term investments.

- Your average electricity bills are high or you don’t have access to utility grid power.

Zoning and Permitting Issues

The zoning and permitting processes for wind energy installations seek to address safety, aesthetics, and community interests and concerns. Some of these concerns might include sound level, visual impact, wildlife impact, TV/radio interference, ice shedding, or broken equipment.

You can find out more about zoning and permitting requirements by:

- Contacting the local building inspector, board of supervisors, or planning board. They can tell you if you will need to obtain a building permit and will provide you with a list of requirements.

- Visiting the Distributed Wind Energy Association’s Permitting and Zoning Resource Center.

- Utilizing the Clean Energy States Alliance’s Distributed Wind Energy Zoning and Permitting: A Toolkit for Local Governments.

What Size Wind Turbine Do I Need?

The size of the wind turbine you need depends on your application. Small turbines range in size from 20 Watts to 100 kilowatts (kW). The smaller or “micro” (20- to 500-Watt) turbines are used in applications such as charging batteries for recreational vehicles and sailboats.

One- to 10-kW turbines can be used in applications such as pumping water.

Turbines used in residential applications can range in size from 400 Watts to 100 kW (100 kW for very large loads), depending on the amount of electricity you want to generate.

A typical home uses approximately 10,649 kilowatt-hours (kWh), an average of 877 kWh per month. Depending on the average wind speed in the area, a wind turbine rated in the range of 5 to 15 kW would be required to make a significant contribution to this demand. A 1.5-kW wind turbine will meet the needs of a home requiring 300 kWh per month in a location with a 14 MPH (6.26 meters per second) annual average wind speed.

The manufacturer, dealer, or installer can provide you with the expected annual energy output of the turbine as a function of annual average wind speed. The manufacturer will also provide information about any maximum wind speeds at which the turbine is designed to operate safely. Most turbines have automatic overspeed-governing systems to keep the rotor from spinning out of control in extremely high winds.

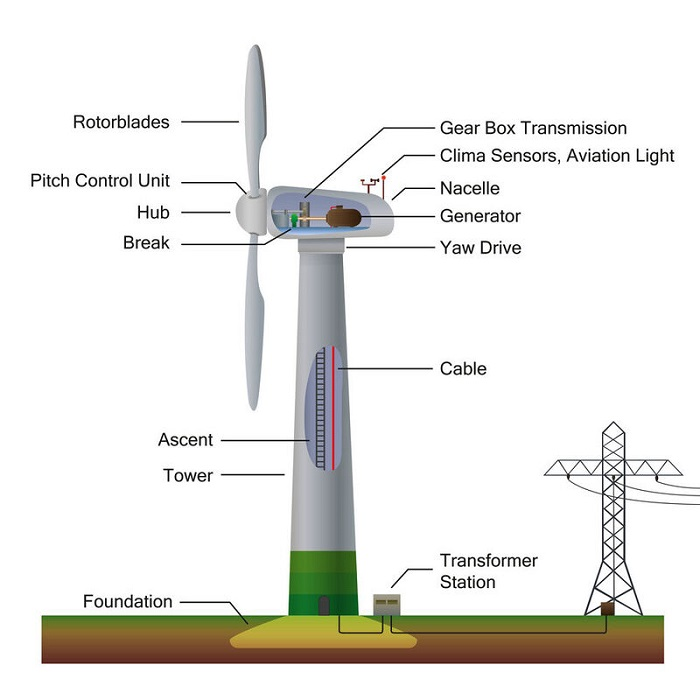

What Are the Basic Parts of a Small Wind Electric System?

- Wind Turbine

- Tower

- Balance of System

- Batteries for Stand-Alone Systems

- Inverters for Grid-Connected Systems

- Generator

- Rotor

Wind Turbine

Small wind turbines can be divided into two groups: horizontal axis and vertical axis. The most commonly used turbine in today’s market is the horizontal-axis wind turbine.

Savonius : A Savonius turbine can be recognized by its “S” shaped design when viewed from above.

Darrieus : A darrieus turbines look like an eggbeater and have vertical blades that rotate into and out of the wind.

Generator

Mounted on a frame, it converts the rotary motion from the rotor into electrical energy.

Rotor

The blades that capture the kinetic energy of the wind and convert it into rotary motion.

Tower

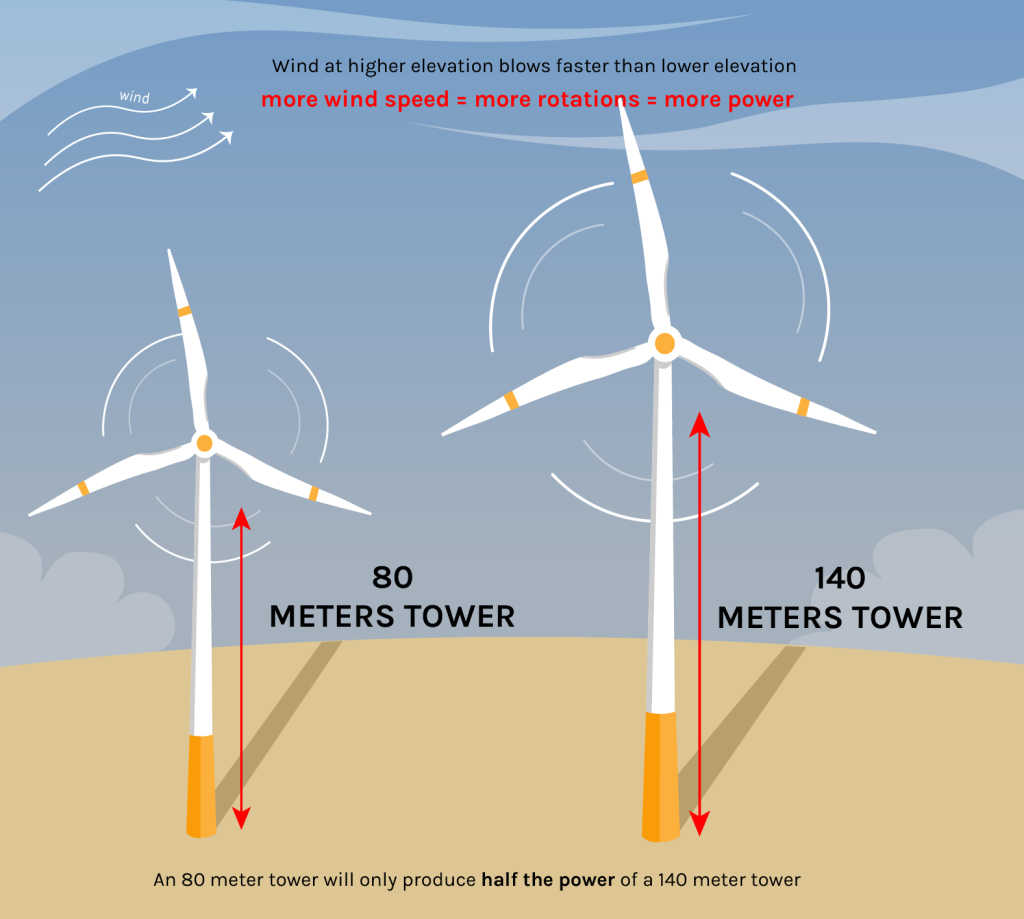

The tower of a small wind electric system is a crucial structural component designed to elevate the wind turbine to a height where it can capture stronger and more consistent winds.

The most common design for small turbines is the tubular monopole tower, often made of steel, with a tapered or conical shape for strength and cost-effectiveness.

Key aspects of the tower include:

- Height: The tower height is optimized to maximize wind exposure while minimizing material costs and structural loads. Common hub heights for small turbines range around 20-30 meters.

- Structure: Tubular monopole towers have a smooth cylindrical shape, which simplifies manufacturing, transport, and installation. Some are built with slip-fit joint sections for easier assembly.

- Strength and Stability: The tower must endure various loads including the thrust from the turbine rotor, wind pressure on the structure, and the turbine’s own weight. It is designed to resist bending, buckling, and vibrations.

- Deflection Limits: The tower should not deflect (bend) beyond a small fraction (e.g., about 1% of its height) to protect the turbine and maintain operational integrity.

- Foundation: A properly designed foundation anchors the tower securely to the ground to withstand these loads.

- Electrical Protection: The tower also houses the wiring for power transmission from the turbine down to the base and must protect these cables adequately.

Balance of System

- Costs in addition to the turbine and the tower are the balance of system, including parts and labor, which will depend on your application.

- The balance of system equipment required will also depend on whether the system is grid-connected, stand-alone, or part of a hybrid system.

- For a residential grid-connected application, the balance of system parts may include a controller, storage batteries, a power conditioning unit (inverter), wiring, foundation, and installation.

- Many wind turbine controllers, inverters, or other electrical devices may be stamped by a recognized testing agency, such as Underwriters Laboratories or Intertek.

Batteries for Stand-Alone Systems

- Stand-alone systems (systems not connected to the utility grid) require batteries to store excess power generated for use when the wind is calm. They also need a charge controller to keep the batteries from overcharging.

- Deep-cycle batteries, such as those used for golf carts, can discharge and recharge 80% of their capacity hundreds of times, which makes them a good option for remote renewable energy systems.

- Automotive batteries are shallow-cycle batteries and should not be used in renewable energy systems because of their short life in deep-cycling operations.

Small wind turbines generate direct current (DC) electricity. In very small systems, DC appliances operate directly off the batteries. If you want to use standard appliances that use conventional household alternating current (AC), you must install an inverter to convert DC electricity from the batteries to AC. Although the inverter slightly lowers the overall efficiency of the system, it allows the home to be wired for AC, a definite plus with lenders, electrical code officials, and future homebuyers.

For safety, batteries should be isolated from living areas and electronics because they contain corrosive and explosive substances. Lead-acid batteries also require protection from temperature extremes.

Inverters for Grid-Connected Systems

In grid-connected systems, the only additional equipment required is a power conditioning unit (inverter) that makes the turbine output electrically compatible with the utility grid. Batteries are usually not required.

Fabrication and Prototype Design

The design of wind turbine fabrication and prototype design can be summarized in points as follows:

- Component Fabrication: Manufacture major parts separately including blades, tower, nacelle, and control systems.

- Blade Manufacturing: Mold, shape, cure, and finish blades from composite materials such as fiberglass reinforced resin.

- Tower Construction: Cut, shape, and weld steel or concrete sections to create structural support.

- Nacelle Assembly: Assemble housing with generator, gearbox, control systems, and wiring.

- Prototype Assembly: Combine all components including blades, nacelle, and tower for prototype creation.

- Testing and Commissioning: Conduct electrical, mechanical, and performance tests to validate prototype functionality.

- Use of Automated Processes: Employ CNC cutting, welding machinery, and automation to improve fabrication accuracy and efficiency.

- Quality Control: Monitor weld quality, material integrity, and finish to meet design specifications.

- Foundation Preparation: Design and construct a foundation tailored to location for secure turbine installation.

- Iterative Improvement: Prototype testing leads to design refinement before final production.

These steps collectively form the structured process to design, fabricate, and test a wind turbine prototype ready for real-world application.

Performance Testing and Results

Design of Wind Turbine Performance Testing and Results can be summarized in points as follows:

- Performance testing measures the electric power output of a wind turbine against wind speed and site-specific conditions to verify efficiency and energy production.

- Accurate wind speed measurement is done using meteorological masts or remote sensing devices like LiDAR, ensuring data quality.

- The testing process involves characterizing the power curve of the turbine, measuring the mechanical and electrical performance, and assessing turbine availability.

- Data is analyzed to identify anomalies, deviations from the expected power curve, and to inform improvements in turbine operation.

- Tests include evaluation of parameters like yaw control, rotational speed, blade pitch, and power output under different wind and operational conditions.

- Corrections for atmospheric density and terrain-induced effects (turbulence, shear, veer) are applied for precise performance assessment.

- Results help confirm the turbine’s compliance with design and warranty specifications and provide data for optimizing annual energy production.

- Performance testing also helps detect mechanical issues such as rotor imbalance or electrical system faults.

- Advanced tools and expert data analysis are employed for trustworthy and actionable results to improve turbine reliability and output.

Economic Analysis of Wind Turbines

- Feasibility assessments evaluate the cost-effectiveness of wind projects by analyzing factors such as initial investment, operational, and maintenance costs.

- Levelized Cost of Energy (LCOE): Large turbines, typically between 1,000–3,000 kW, tend to have lower LCOEs compared to smaller turbines, making them more economically viable over their lifespan.

- Investment viability depends on local electricity prices, power purchase agreements (PPAs), and government incentives like tax credits.

- Cost-benefit analysis is critical, comparing total project costs against expected energy revenues to determine profitability.

- Funding and financing options include support mechanisms like feed-in tariffs, subsidies, or participation in clean development mechanisms (CDM).

- Economic benefits extend beyond direct electricity sales, contributing to regional development and potential poverty alleviation.

Environmental Analysis

- Site selection considers environmental constraints, such as wildlife habitat, land-use restrictions, and noise levels, to minimize ecological impacts.

- Environmental siting involves ensuring the project complies with regulations and reduces adverse impacts on local ecosystems.

- Renewable energy contribution helps reduce greenhouse gas emissions and reliance on fossil fuels, supporting climate change mitigation goals.

Challenges and limitations

The design of wind turbines faces several key challenges and limitations summarized as follows:

- High initial costs and economic competitiveness issues.

- Efficiency and performance variances, especially in small and vertical axis turbines.

- Structural and design limitations to withstand diverse and dynamic loads including turbulence, wind shear, and offshore environmental forces.

- Difficulty in accurately modeling inflow and operating conditions, affecting design reliability.

- Manufacturing and transportation challenges due to large blade sizes and component complexity.

- Noise production and visual impact concerns affecting social acceptance.

- Maintenance difficulties and wear under real-world turbulent conditions.

- Optimization complexity for site-specific terrain and atmospheric variations.

- Limitations in scaling lightweight yet strong structures for larger turbines.

- Uncertainties in wind farm wake effects and dynamic interaction among multiple turbines.

Future Scope and Improvements

- Increasing turbine capacity and size to capture more wind energy efficiently, reducing costs per megawatt-hour.

- Developing taller towers to access stronger and more consistent winds at higher altitudes.

- Innovating aerodynamic blade designs with adaptive, sensor-equipped blades for real-time optimization and stress reduction.

- Incorporating bio-inspired designs for improved lift and reduced drag.

- Advancing variable-speed turbines to optimize energy output under varying wind conditions.

- Expanding vertical axis turbines and mini/micro turbines for urban and decentralized energy applications.

- Integrating digital technologies such as AI, real-time monitoring, predictive maintenance, and digital twins to enhance performance and reduce operational costs.

- Enhancing scalability through modular designs and hybrid systems combining wind with solar or energy storage for stable power supply.

- Focusing on sustainability with net-zero carbon production, recyclable turbine materials, and lifecycle cost reductions.

- Exploring emerging technologies like airborne wind energy systems (kite- or drone-based turbines) to harness high-altitude winds.

Conclusion

The design of a wind turbine focuses on creating an efficient and reliable system that converts wind energy into electrical power by optimizing key components such as rotor blades, generator, and tower. It balances aerodynamic efficiency, structural strength, and cost-effectiveness to ensure optimal performance and durability in various wind conditions. Proper design also addresses system control, safety, and integration with electrical grids or storage systems, making wind turbines a sustainable and practical solution for renewable energy generation.