Aggregates are essential components in construction, mainly used as fillers in concrete to provide strength, durability, and overall performance. They constitute about 60-80% of concrete volume, influencing its mechanical properties and cost.

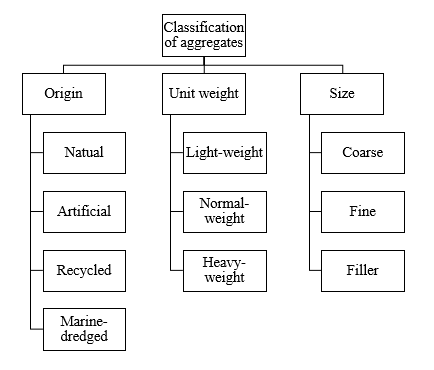

Aggregates are classified based on several criteria including their size, source, shape, and density, which helps in selecting the right type for specific construction purposes. The main categories include fine aggregates (such as sand) and coarse aggregates (such as gravel and crushed stone) based on size, as well as natural aggregates from rocks and artificial aggregates produced by industrial processes.

Aggregates

Aggregates can also be grouped by their source, ranging from naturally occurring materials like sand and gravel to manufactured aggregates derived from industrial by-products, promoting sustainability. Furthermore, unit weight-based classification highlights their role in producing concrete with varying densities, from lightweight panels to heavy-duty radiation shields.

Classification of Aggregates Based on Size

The characteristics of concrete in both its fresh and hardened forms are significantly influenced by the size of the particles. Aggregate sizes can vary from tiny particles to a few centimetres. To ensure best performance, aggregates of any size must be graded so that the mix’s various particle size fractions are suitably matched.

The term “grading of the aggregate” refers to this dispersion of particle sizes. Fine aggregate, coarse aggregate, all-in aggregate, and single-size aggregate are the four size-based categories into which aggregates are divided.

Fine Aggregate

Fine aggregates are small-sized, inert granular materials used primarily in construction, especially in concrete and mortar mixes.

- Definition:

Fine aggregate consists of particles that predominantly pass through a 4.75 mm IS sieve while retaining only as much coarser material as specified by standards. - Particle Size Range:

- Lower limit: Approximately 0.07 mm.

- Particles smaller than 0.06 mm are classified as silt, while those under 0.002 mm are referred to as clay.

- Deposits with sand, silt, and clay in similar proportions are termed loam.

- Types of Fine Aggregate:

- Natural Sand: Derived from the natural disintegration of rock or deposition by streams and glacial processes.

- Crushed Stone Sand: Produced by crushing hard stones.

- Crushed Gravel Sand: Created by crushing natural gravel.

- Grading Zones:

According to IS: 383–1970, fine aggregate is divided into four grading zones, which progressively become finer from Zone I to Zone IV. - Sub-Classifications Based on Size:

- Coarse sand.

- Medium sand.

- Fine sand.

Fine aggregates play a crucial role in enhancing the workability, finish, strength, durability, and dimensional stability of the concrete.

Their properties such as size, shape, texture, water absorption, and fineness modulus significantly influence the quality of the concrete mix and overall structural integrity.

They typically make up 35% to 45% of the total concrete volume and help reduce the cement requirement by filling spaces between coarse aggregates.

Coarse Aggregates

They include gravel, crushed stone, and other durable materials used primarily in concrete construction to provide volume, strength, and stability.

- Definition:

Coarse aggregate consists of particles predominantly retained on a 4.75 mm IS sieve, containing only as much fine material as permitted by specifications. - Types of Coarse Aggregate:

- Crushed Gravel or Stone: Obtained by crushing hard stone or gravel.

- Uncrushed Gravel or Stone: Formed by the natural disintegration of rock.

- Partially Crushed Gravel or Stone: A blend of crushed and uncrushed materials.

- Nominal Size:

Coarse aggregates are typically described by their nominal size, such as 40 mm, 20 mm, 16 mm, and 12.5 mm. For instance, a 20 mm nominal size aggregate means most particles pass through a 20 mm IS sieve, with the majority retained on a 10 mm IS sieve. - Properties Influenced by Parent Rock:

Coarse aggregate inherits many properties from its parent rock, such as:- Chemical and mineral composition.

- Specific gravity, strength, and stability.

- Pore structure and hardness.

Additional properties like particle shape, surface texture, and absorption influence the performance of concrete but are not inherent to the parent rock.

All-in Aggregate

All-in aggregate is commonly used for filling and leveling purposes, such as repairing small cracks, as a base or sub-base layer in pavement construction, and in applications where a uniform mix of aggregate sizes is beneficial to achieve compaction and stability.

- Definition:

This refers to naturally available aggregates comprising a mix of fine and coarse fractions. - Applications:

Adjustments are often necessary to supplement grading with deficient size fractions. While convenient, all-in aggregates are not typically used for high-quality concrete, as their properties might not meet the stringent requirements of structural applications. - Nominal Size:

Similar to coarse aggregates, all-in aggregates are also described by their nominal size.

Single-Size Aggregate

Single-size aggregates consist of particles that fall within a narrow size range, meaning most of the aggregate particles pass through one specified sieve size and are largely retained on the next smaller sieve

- Definition:

Single-size aggregates consist of particles falling within a narrow size range. - Examples:

- A 20 mm single-size aggregate refers to aggregates where most particles pass through a 20 mm IS sieve, with the majority retained on a 10 mm IS sieve.

- Applications:

These aggregates are used for specific construction needs, such as producing uniform textures or achieving precise grading requirements.

Classification of Aggregates Based on Source

1. Natural Aggregates

Natural aggregates are granular materials obtained directly from natural sources such as quarries, riverbeds, and glaciers without undergoing extensive processing aside from breaking, washing, or grading.

They consist mainly of particles like crushed stone, sand, and gravel, which retain their natural mineralogical and physicochemical properties. Common minerals composing natural aggregates include quartz, feldspar, and calcite, contributing to their strength, durability, and resistance to environmental effects.

These aggregates form the backbone of construction materials like concrete and asphalt, ensuring sustainability and structural integrity by maintaining good grading, shape, low porosity, and high specific gravity. Their natural texture helps improve bonding with cement, enhancing the overall strength and longevity of construction projects.

2. Manufactured (Synthetic) Aggregates

Manufactured (synthetic) aggregates are artificial materials created by processing natural substances or industrial by-products through mechanical, thermal, or chemical means. Commonly produced by heating raw materials like clay or shale in rotary kilns, these aggregates expand and harden to form lightweight, porous, and durable materials suitable for construction.

Types of manufactured aggregates include expanded clay, shale, slate, sintered fly ash, and slag aggregates. They are often used when natural aggregates are scarce or when specific properties like reduced weight or enhanced insulation are needed.

Manufactured aggregates are used in concrete, asphalt mixes, and other construction materials, providing benefits such as lower density, improved workability, and environmental advantages by recycling industrial waste.

Classification of Aggregate Based on Unit Weight

- Ultra-Lightweight Aggregate

- Lightweight Aggregate

- Normal-Weight Aggregate

- Heavy-Weight Aggregate

Ultra-Lightweight Aggregate

Ultra-lightweight aggregates are a special class of lightweight aggregates characterized by very low density, often below 800 kg/m³, which significantly reduces the weight of concrete made with them.

These aggregates typically have high porosity and low strength but provide excellent thermal insulation and acoustic properties. Common materials used as ultra-lightweight aggregates include expanded perlite, expanded vermiculite, and recycled glass.

Ultra-lightweight aggregates are primarily used in applications requiring weight reduction, such as precast panels, insulating concrete, and structural elements where reducing the dead load is critical. While they improve thermal efficiency, the mechanical strength of concrete made with ultra-lightweight aggregates is usually lower compared to normal aggregates, so they are often used in non-load-bearing or lightly loaded structures.

Lightweight Aggregate

Lightweight aggregates are coarse aggregates with low density, used primarily to produce lightweight concrete for both structural and non-structural applications.

Their density typically ranges from about 500 kg/m³ to 1800 kg/m³, which is significantly lighter than normal aggregates that have densities between 2300 to 2500 kg/m³.

Lightweight aggregates improve thermal insulation, reduce dead loads in structures, and often exhibit good acoustic properties.

They may be formed naturally or manufactured and have a porous structure that absorbs less water, enhancing the concrete’s workability and insulating performance.

Structural Lightweight Concrete (SLWC) made with these aggregates can achieve compressive strengths close to normal concrete and is widely used in building construction to reduce overall weight and improve economy.

Normal-Weight Aggregate

Normal-weight aggregate refers to common types of aggregates like sand, gravel, and crushed stone that are typically used in concrete.

They have bulk densities generally ranging from about 1120 to 1760 kg/m³ and relative densities (specific gravities) roughly between 2.55 and 2.75. Normal-weight aggregates are the most commonly used in construction and make up about 90% of concrete use.

They affect the workability and durability of concrete and are distinguished from lightweight and heavyweight aggregates by their density and specific gravity characteristics.

Key points about normal-weight aggregates:

- Comprise materials such as sand, gravel, and crushed stone.

- Bulk density range typically around 1120 to 1760 kg/m³.

- Specific gravity usually between about 2.55 and 2.75.

- Constitute around 90% of the concrete aggregate usage in markets like the United States.

- Influence concrete properties such as workability and durability but not necessarily strength directly.

This classification contrasts with lightweight aggregates, which have lower densities and are used for reducing concrete weight, and heavyweight aggregates, used for applications like radiation shielding due to their high density.

Therefore, normal-weight aggregates are the standard aggregates that provide typical concrete a density range compatible with most conventional construction needs.

Heavy-Weight Aggregate

Heavy-weight aggregate refers to aggregates that have relatively high densities and specific gravities, typically with a specific gravity of 2.4 or higher and bulk densities above about 2400 kg/m³.

These aggregates are used to produce heavy weight concrete, which has a density substantially higher than normal concrete—often around 2600 kg/m³ or more.

Heavyweight aggregates can be natural minerals such as magnetite, hematite, barite, ilmenite, and serpentine, or synthetic materials like steel and iron scrap.

Because of their high density, heavy weight aggregates are used where high mass per unit volume is needed, such as radiation shielding in nuclear plants, X-ray laboratories, medical facilities, ballast for underwater pipelines, and counterweights.

Key properties and types:

- Specific gravity generally above 2.4, often 3.0 or higher.

- Bulk densities ranging from approximately 2100 to over 4600 kg/m³ depending on material.

- Common natural heavy aggregates: magnetite, hematite, barite, ilmenite, limonite.

- Common synthetic heavy aggregates: steel scrap, ferrophosphorus.

- Heavyweight concrete mixes achieve densities from about 2600 kg/m³ up to 5200 kg/m³.

- Typically resist radiation, vibration, and sound, and can endure high temperatures.

- The use of heavy aggregates often leads to concrete with unit weights about 50-60% higher than normal concrete.

Applications:

- Radiation shielding in hospitals and nuclear power plants.

- Counterweights in cranes and stabilizers.

- Sound and vibration attenuation.

- Weight coatings for underwater structures.

Classification of Aggregates Based on Shape

The workability, cohesiveness, and bond strength of fresh concrete are all significantly influenced by the shape of the particles. The shape is crucial for obtaining the intended structural performance even though it has less of an impact on the characteristics of hardened concrete.

Based on the morphology of the particles, aggregates are often divided into four groups: angular, flaky or elongated, irregular or partially rounded, and rounded.

Rounded Aggregates

These have smooth, rounded particles typically formed by natural weathering and erosion, such as riverbed or seashore gravel. However, they provide poor interlocking and bond strength, making them less ideal for high-strength concrete.

Characteristics:

Derived from natural sources like river or seashore gravel.

Contain minimum voids, typically 32–33%, resulting in a lower surface area-to-volume ratio.

Require less cement paste for the same workability, reducing material costs.

Advantages:

Excellent for producing economical and workable concrete.

Limitations:

Poor interlocking between particles, leading to weak bond development.

Unsuitable for high-strength concrete and load-bearing pavements due to reduced structural integrity.

Irregular Aggregates

Irregular aggregates, also known as partly rounded aggregates, are shaped by attrition with somewhat rounded edges but still maintain some angularity. Due to their irregular shape, they develop a good bond with cement paste, making them suitable for ordinary concrete.

- Characteristics:

- Partly rounded particles sourced from materials like pit sand and gravel.

- Contain voids in the range of 35–38%, requiring more cement paste for adequate workability.

- Advantages:

- Slightly better interlocking than rounded aggregates.

- Limitations:

- Still inadequate for high-strength or high-performance concrete due to limited bonding capabilities.

Angular Aggregates

Angular aggregates are characterized by sharp, well-defined edges and rough textures, typically produced by mechanically crushing larger rocks such as limestone or granite.

angular aggregates enhance mechanical interlocking and bonding within concrete, contributing to stronger and more stable structures, especially in high-stress or high-traffic contexts.

- Characteristics:

- Sharp-edged, angular, and rough particles, typically from crushed rocks.

- Contain the highest void percentage (38–40%) among all shapes.

- Advantages:

- Excellent interlocking properties, resulting in strong bonding with cement paste.

- Suitable for high-strength concrete, pavements, and tension-resisting structural elements.

- Limitations:

- Require more cement paste to achieve workable concrete due to higher void content.

Flaky and Elongated Aggregates

- Flaky Aggregates: These aggregates have a particle thickness that is less than 60% of their mean size, meaning they are thin and flat. Their high surface area increases water demand and reduces concrete workability. Flaky aggregates tend to have poor interlocking capacity, leading to increased voids, lower density, and reduced load-bearing capacity. They can more easily break down under stress, adversely affecting concrete strength and durability.

- Elongated Aggregates: These have a length greater than 1.8 times their mean dimension, meaning they are long and narrow. Like flaky aggregates, elongated shapes increase water demand and reduce workability, and their shape can lead to challenges in compaction and a lower overall stability of the concrete mixture.

- Effects on Concrete:

- Reduced workability and durability, as flaky and elongated particles tend to orient in one plane, creating voids beneath.

- Adverse effects on the concrete’s compressive and flexural strength.

- Recommendations:

- Limit flaky and elongated particles to 10–15% of the total aggregate volume, particularly for crushed fine aggregates.

- Use proper tests like flakiness index and elongation index (as per IS: 2386-1963) to control particle shapes.

Conclusions

The classification of aggregates is essential for selecting the right material for construction work. Aggregates are generally classified based on source (natural or artificial), size (fine or coarse), shape (rounded, angular, or flaky), and density (lightweight, normal weight, or heavy weight). Each type plays a specific role in determining the strength, durability, and workability of concrete and other construction materials.