Building Materials for Affordable Housing innovative materials that prioritize low cost, durability, and sustainability to address global shelter needs. This opening section emphasizes the urgency of affordable housing amid urbanization and population growth, highlighting how material choices directly impact project budgets, timelines, and environmental footprints.

Affordable housing requires materials that are cost-effective, durable, and environmentally friendly. The choice of building materials plays a crucial role in reducing construction costs while maintaining quality and sustainability.

This blog explores some of the most commonly used and innovative building materials that are ideal for affordable housing projects.

Building Materials for Affordable Housing

- Concrete

- Steel

- Structural Insulated Panels (SIPs)

- Straw bales

- Wood and engineered wood products

- Gypsum board

- Shipping containers

- Fiberglass and Foam Insulation

Concrete

Concrete remains a cornerstone of affordable housing due to its unmatched availability, low cost, and robust performance against fire, weather, and pests. Its versatility in foundations, walls, floors, and prefabricated panels enables rapid, scalable construction for budget projects worldwide.

Why It’s Used

Concrete’s affordability stems from abundant raw materials like cement, sand, and aggregates, often sourced locally to slash transport expenses by 20-30%. It offers exceptional durability, with compressive strengths exceeding 3,000 psi, ensuring decades of service in harsh climates without frequent repairs.

Key Applications

Foundations benefit from concrete’s load-bearing capacity, preventing settling in low-cost homes, while walls and floors leverage precast panels for 2-3x faster assembly than traditional pours. These panels arrive site-ready, minimizing labor in remote or urban infill builds.

Advancements Explored

Lightweight concrete incorporates aggregates like expanded clay or foam, cutting density by up to 40% to ease handling and reduce foundation sizes by 15-25%, ideal for multi-story affordable units. Recycled concrete reuses demolition waste as aggregate, diverting 1 ton per cubic yard from landfills while matching standard strength at 10-20% lower cost.

Additional Benefits

Both variants boost sustainability: lightweight versions improve insulation for 25% energy savings, and recycled options lower embodied carbon by reusing materials. They enhance seismic resilience through reduced dead loads, making them perfect for disaster-prone affordable housing zones.

Steel

Steel excels in affordable housing for its superior strength-to-weight ratio and prefabrication potential, enabling robust framing that withstands heavy loads while keeping material costs low. Its non-combustible nature and recyclability further enhance its appeal for safe, sustainable builds.

Why It’s Used

Steel’s versatility supports complex designs from single-family homes to multi-story apartments, with prefabricated components assembled 50-70% faster than wood or masonry, slashing labor expenses by up to 30%. Corrosion-resistant coatings extend lifespan in humid or coastal areas, minimizing long-term maintenance.

Key Applications

Structural frames provide open spans for flexible interiors in multi-story buildings, while roofing sheets offer durable, low-pitch options that reduce weight on foundations. Modular units stack efficiently for urban density, ideal for rapid-deployment social housing projects.

Advancements Explored

Cold-formed steel (CFS), or light-gauge steel, uses thin, roll-formed profiles that are 30-50% lighter than hot-rolled alternatives, easing transport and enabling smaller crews for on-site erection. Recycled steel, comprising over 90% scrap in many products, cuts embodied carbon by 40% and costs 10-20% less, supporting green certifications like LEED.

Additional Benefits

These innovations minimize waste through precise BIM integration, boost energy efficiency with integrated insulation, and improve seismic performance via ductility. In affordable projects, they deliver scalable quality, often completing complexes in months rather than years.

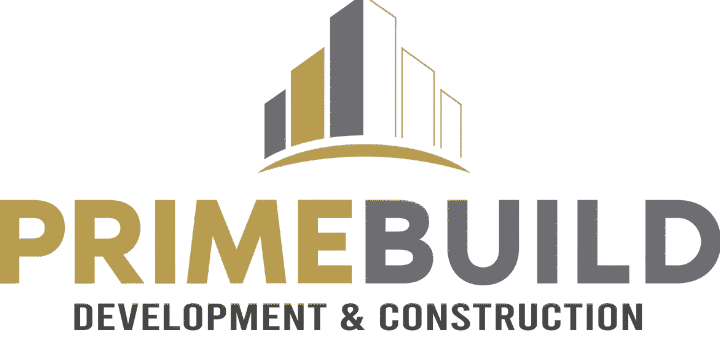

Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPs) streamline affordable housing by integrating rigid insulation between structural facings like oriented strand board, delivering both strength and thermal performance in factory-made units. They cut build times by up to 55% and energy use by 40-60%, making them ideal for rapid, efficient projects.

Why It’s Used

SIPs combine insulation and load-bearing capacity into airtight panels that minimize thermal bridging, reducing heating costs and enhancing occupant comfort in budget homes. Prefabrication eliminates on-site waste and weather delays, with labor savings of 30-40% over stick-built methods.

Key Applications

Walls form the backbone of modular homes, providing straight, durable enclosures ready for siding or cladding, while roofs and floors enable open spans and quick decking for multi-unit developments. Their versatility suits everything from single-family dwellings to low-rise apartments in high-demand areas.

Advancements Explored

Bio-based SIPs swap foam cores for natural fillers like straw, hemp, or mycelium, boosting sustainability with carbon sequestration and renewability while maintaining R-values above 40 per inch. These eco-variants reduce embodied carbon by 50% and appeal to green building standards like LEED.

Additional Benefits

SIPs enhance fire resistance, seismic stability, and soundproofing, with lifespans exceeding 100 years and minimal maintenance. In affordable housing, they enable net-zero designs, slashing utility bills by 50-60% and supporting scalable solutions for housing shortages.

Straw bales

Straw bales transform agricultural waste into a powerhouse for affordable, eco-friendly housing through their exceptional insulation and minimal cost. They provide thick walls with R-values of 1.5-3 per inch, enabling passive heating and cooling that slashes energy bills by 50-75% in rural or off-grid settings.

Why It’s Used

Abundant from crop harvests, straw bales cost $3-7 per bale locally, far below conventional insulation, while their breathable structure regulates humidity to prevent mold. Fire tests show plastered bales outperform wood frames, withstanding flames for over 2 hours due to low oxygen access inside dense bales.

Key Applications

As wall infill between timber posts in load-bearing or post-and-beam designs, they suit single-story homes in dry climates like the U.S.

Southwest or parts of Europe. Rural sustainable projects stack bales for curved or straight walls up to 24 inches thick, finished with lime plaster for weatherproofing.

Advancements Explored

Treated bales incorporate borate solutions for pest resistance and enhanced fire retardancy, passing ASTM E119 standards while maintaining insulation. Prefabricated straw panels compress bales into shippable units, cutting on-site labor by 40% and enabling urban modular builds with machine-compressed density over 120 kg/m³.

Additional Benefits

Straw sequesters carbon permanently, offers superior sound absorption (STC ratings above 50), and builds on weak soils due to low weight. With proper detailing, structures last 100+ years, making them a resilient choice for community-led affordable housing initiatives.

Wood and engineered wood products

Wood and engineered wood products stand out in affordable housing for their renewability from managed forests, low cost per square foot, and ease of cutting, nailing, or milling on-site.

They weigh less than concrete or steel, simplifying transport and installation for small crews in remote or community-led builds.

Why It’s Used

Sourced locally in many regions, wood costs 20-40% less than imported alternatives while sequestering carbon during growth, and its natural insulation (R-value around 1 per inch) cuts heating needs.

Workability allows rapid framing without heavy machinery, ideal for owner-builders aiming to save on labor.

Key Applications

Framing forms skeletons for walls and roofs in single- or low-rise homes, while flooring like plywood subfloors provides smooth, durable surfaces. Prefabricated panels, such as wall sections or roof trusses, enable modular homes assembled in days, suiting mass housing projects.

Advancements Explored

Cross-Laminated Timber (CLT) glues layers of lumber in perpendicular orientations for concrete-like strength, supporting spans up to 50 feet in mid-rise buildings while reducing construction time by 30-50% through off-site prefab.

Reclaimed wood from barns or pallets offers weathered aesthetics for accents at 50% lower cost, diverting landfill waste.

Additional Benefits

These options enhance seismic flexibility, fire charring for protection, and acoustic dampening, with CLT enabling taller affordable apartments. They align with green codes, lowering lifecycle costs through durability over 75 years and minimal processing energy.

Fiberglass and Foam Insulation

Fiberglass and foam insulation boost energy efficiency in affordable housing by creating thermal barriers that cut heating and cooling costs by 40-60% for low-income residents. Both options install quickly without specialized tools, fitting tight budgets while adding soundproofing for quieter living spaces.

Why It’s Used

Fiberglass batts or rolls cost $0.30-0.80 per sq ft and resist fire/mold, lasting 20+ years with minimal settling. Foam boards or blown-in variants fill gaps seamlessly, enhancing airtightness in walls to stabilize indoor temperatures year-round.

Key Applications

Walls receive friction-fit batts between studs for R-13 to R-21 values, ceilings use blown-in for attics up to R-49, and floors insulate crawlspaces against ground chill. They suit multi-family units by reducing noise transmission between apartments.

Advancements Explored

Spray foam expands on-site for R-6+ per inch, sealing cracks 50% better than batts and preventing air leaks that waste 20-30% of energy. Bio-based foams from plant oils lower environmental impact while matching performance in retrofits.

Additional Benefits

These materials improve indoor air quality by blocking allergens and moisture, support green certifications, and pay back via utility savings within 2-5 years. In affordable projects, they enable code-compliant efficiency without premium pricing.

Gypsum board

Gypsum board, commonly known as drywall, serves as a staple in affordable housing for its rock-bottom price and straightforward installation that requires minimal tools or skilled labor. It delivers a seamless, paint-ready surface while providing inherent fire resistance from its gypsum core, which releases water vapor under heat to slow flame spread.

Why It’s Used

Priced at $0.30-0.60 per square foot, gypsum outperforms plaster in speed and cost, cutting interior finishing time by 70% and enabling same-day taping and mudding. Its non-structural lightness reduces framing demands, ideal for budget renovations or modular inserts.

Key Applications

Interior walls create partitions in apartments or homes, offering sound dampening up to STC 45 when doubled, while ceilings hide joists for a clean drop effect. It suits high-volume projects like multi-family units where rapid turnover keeps schedules tight.

Advancements Explored

Recycled gypsum panels incorporate 90-95% post-consumer waste, such as drywall scraps, thereby slashing virgin mining by 80% and reducing landfill diversion. These panels also match Type X fire ratings for 1-2 hour assemblies. Synthetic gypsum from power plant scrubbers further cuts emissions, supporting green builds at no cost premium.

Additional Benefits

Moisture-resistant variants prevent mold in baths, and flex boards enable curves for modern designs; overall, it boosts durability with impact resistance when backed by studs. In affordable contexts, it lowers life-cycle costs through easy repairs and spans of 50 years or more.

Shipping containers

Shipping containers revolutionize affordable housing by repurposing surplus steel units originally built for global transport, offering inherent durability against extreme weather, pests, and seismic activity at a fraction of traditional build costs. Their stackable, modular design enables rapid deployment, often completing projects in weeks rather than months.

Why It’s Used

Priced at $2,000-5,000 per used 40-foot unit, containers cut material expenses by 40-60% versus site-built homes, with weather-tight shells that require no immediate framing. High-tensile steel (Corten grade) ensures 50+ year lifespans, minimizing repairs in low-income communities.

Key Applications

Tiny homes utilize single 20- or 40-foot containers for compact, mobile dwellings under 400 sq ft, perfect for urban lots or disaster relief. Multi-unit projects stack or join 4-12 containers into apartments, maximizing density on small footprints for workforce housing or student residences.

Advancements Explored

Retrofitting adds spray-foam insulation (R-20+), HVAC systems, and windows via plasma cutting, transforming industrial shells into comfortable spaces with electrical/plumbing runs in 1-2 weeks. Hybrid designs integrate solar panels and green roofs, achieving net-zero energy while boosting resale value by 20-30%.

Additional Benefits

Portability allows relocation via flatbed trucks, and sustainability diverts 1,200 lbs of steel per container from scrapyards. They excel in codes with minimal foundation needs, supporting equitable housing in high-cost areas through creative zoning compliance.

When selecting materials for affordable housing, key factors ensure projects stay within budget while delivering safe, lasting structures. Balancing cost, durability, sustainability, availability, and ease of use drives optimal choices tailored to local needs.

Factors to Consider When Choosing Materials

- Cost Breakdown

- Durability Essentials

- Sustainability Focus

- Availability Strategies

- Ease of Use

Cost

Affordability is one of the most important factors, especially for budget-conscious housing projects. Selecting cost-effective materials helps keep the overall construction expenses within limits without compromising basic quality and safety.

Durability

Construction materials must be strong and long-lasting. They should be able to withstand local environmental conditions such as heat, rain, humidity, wind, or earthquakes to ensure the building remains safe and functional over time.

Sustainability

Using eco-friendly and sustainable materials helps reduce environmental impact. Such materials often improve energy efficiency, lower carbon emissions, and reduce long-term maintenance and energy costs.

Availability

Locally available materials are preferred because they reduce transportation costs and construction delays. Using local resources also supports local industries and boosts the regional economy.

Ease of Use

Materials that are easy to handle, install, or assemble can significantly reduce labor costs and construction time. Prefabricated and modular construction materials are especially beneficial for fast and efficient building processes.