The Aggregate Crushing Value Test, a key measure of material performance in construction. This comprehensive guide will walk you through the intricacies of the test, highlighting its importance in ensuring structural integrity.

In construction, guaranteeing the quality and durability of materials is critical to the longevity and performance of infrastructure. One key method for assessing the strength of aggregates—the primary materials used in concrete and road construction is the Aggregate Crushing Value test (ACV).

This test provides a practical and reliable measure of how well aggregates withstand crushing under gradually applied compressive loads, offering essential insights into their suitability for real-world applications.

- While individual rock specimens may exhibit impressive compressive strengths ranging from 45 MPa to 545 MPa, these values do not always reflect how aggregates perform within a structural context.

- Factors such as aggregate size, shape, texture, and flaws influence their behavior under load. The Aggregate Crushing Value test bridges this gap by offering a standardized procedure to assess the strength of aggregates in conditions that mimic actual construction environments.

- Lower ACV values signify stronger aggregates that are better suited for high-load applications such as road bases and heavy-duty pavements. In comparison, higher ACV values suggest materials that may crush more easily under pressure.

Significance of the Aggregate Crushing Value Test (ACV) in Construction

The Aggregate Crushing Value (ACV) Test is crucial in determining the strength and durability of aggregates used in construction.

A high ACV indicates weak aggregates that could compromise the structural integrity of buildings and pavements. By evaluating the resistance of aggregates to crushing under pressure, engineers can make informed decisions that enhance the longevity and performance of infrastructure projects.

This test serves not just as a quality check but as a predictive tool that helps prevent future maintenance issues and unexpected failures.

As construction practices evolve, the ACV Test remains a fundamental aspect of material selection, ensuring that every layer of a structure is built on a solid foundation.

- Quality Assessment:

The ACV test offers a standardized method for evaluating the strength of aggregates, ensuring that only materials meeting specific strength criteria are used in construction projects. - Performance Prediction:

By assessing how aggregates respond to compressive loads, the ACV test helps predict how materials will perform under real-world conditions, such as in roads, pavements, and structural concrete. - Material Selection:

Engineers rely on the ACV test to select appropriate aggregates for different applications. Stronger aggregates (lower ACV values) are preferred for high-load structures, while materials with higher ACV values may be suitable for less demanding applications. - Quality Control:

The ACV test ensures consistency in the properties of construction materials. Regular testing helps maintain uniform quality and reduces the risk of material failure. - Compliance Verification:

The test helps confirm that aggregates meet the necessary standards and regulations for specific construction applications, ensuring adherence to industry requirements and safety guidelines.

Test Principles and Requirements of the Aggregate Crushing Value (ACV) Test

The Aggregate Crushing Value test (ACV) is based on a straightforward principle: aggregates are subjected to a controlled compressive load, and their resistance to crushing is measured as a percentage of the material crushed. This provides valuable insights into the strength and durability of the aggregates used in construction projects.

Key Test Specifications:

- Sample Size: Aggregates passing through a 12.5 mm sieve and retained on a 10.0 mm sieve.

- Testing Load: A standard compressive load of 40 tonnes applied gradually.

- Duration: The load is applied steadily over a period of 10 minutes.

- Temperature Conditioning: Aggregates are pre-conditioned by heating at 100-110°C for 4 hours before the test to ensure moisture consistency.

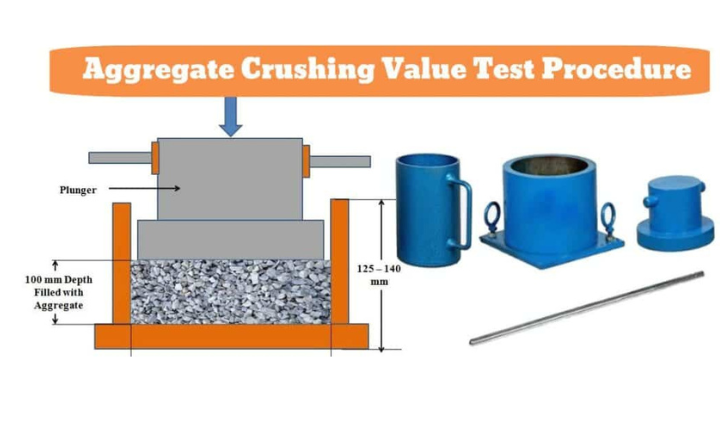

Standardized Equipment for the ACV Test

Imagine a construction site where every material is tested for optimal performance before it’s even laid down. This is the promise of the Aggregate Crushing Value (ACV) Test, which determines the quality of aggregates fundamental to any building project. The ACV test relies on specific apparatus conforming to IS: 2386 (Part IV) – 1963 to ensure accuracy and repeatability of results.

Testing Cylinder:

- Dimensions: 15 cm diameter open-ended steel cylinder.

- Components: Fitted with a plunger and base plate.

- Precision Requirements: Designed with strict dimensional tolerances for reliable measurements.

Supporting Equipment:

- Metal Tamping Rod: 16 mm diameter, 45-60 cm length for compacting the sample.

- Precision Balance: 3 kg capacity with 1 g accuracy for weighing samples.

- Standardized IS Sieves:

- 12.5 mm sieve for selecting aggregates.

- 10.0 mm sieve for retaining the sample.

- 2.36 mm sieve to separate crushed fines after testing.

- Compression Testing Machine: Capable of applying a controlled 40-tonne load.

- Cylindrical Measure: 11.5 cm diameter and 18 cm height for sample preparation.

Pre-Test Conditioning for the Aggregate Crushing Value (ACV) Test

Pre-test conditioning for the ACV test is equally vital, as it prepares the aggregate sample to mimic real-world conditions more accurately. By controlling factors such as moisture content and temperature, practitioners can enhance the relevance of their findings. This practice not only refines the test results but also offers profound insights into how aggregates will perform in situ, taking into account the environmental variables they will face. As we continue to push the boundaries of construction technology, leveraging standardized equipment alongside thorough pre-test conditioning will pave the way for more resilient and sustainable infrastructure.

Initial Selection

- Sieve Criteria:

- Ensure the aggregates are retained on a 10 mm sieve.

- Choose aggregates that pass through a 12.5 mm sieve.

- Sample Quantity:

- Collect a minimum of 3 kg of aggregates to ensure adequate material for testing.

Heat Treatment

- Foreign Material Removal:

- Ensure the sample is free from dust, dirt, and other contaminants.

- Size Distribution:

- Verify that the aggregates have a uniform size distribution within the specified sieve range.

- Surface Dryness:

- Check that the aggregates are adequately surface-dry before testing.

- Quantity Verification:

- Confirm that the sample meets the required 3 kg for accurate and repeatable results.

Detailed Testing Procedure for the Aggregate Crushing Value (ACV) Test

The ACV test procedure involves careful preparation, execution, and processing to ensure accurate and reliable results. Below is a step-by-step guide to the testing process.

Initial Setup:

- Position Cylinder:

- Secure the cylinder on the base plate to ensure stability.

- Record Cylinder Weight (W):

- Weigh the empty cylinder and note the weight (W).

- Prepare Tools:

- Ensure the tamping rod, sieves, and balance are ready for use.

- Equipment Cleanliness:

- Verify that all apparatus is clean and free of dust or residual material.

Sample Loading Process:

- Divide Sample:

- Split the aggregate sample into three equal portions.

- Layered Compaction:

- Place one portion into the cylinder as the first layer.

- Apply 25 tamping strokes with the tamping rod to achieve uniform compaction.

- Repeat for Three Layers:

- Add the remaining portions one layer at a time, applying 25 strokes per layer.

- Record Filled Cylinder Weight (W₁):

- Weigh the cylinder with the aggregate sample and record the weight (W₁).

Test Execution:

- Level Surface:

- Carefully level the surface of the compacted aggregate.

- Insert Plunger:

- Place the plunger horizontally on top of the aggregate.

- Ensure the plunger is properly aligned within the cylinder.

- Position Assembly:

- Place the entire assembly (cylinder, plunger, and base plate) into the compression testing machine.

- Apply Load:

- Gradually apply a load of 40 tonnes over a period of 10 minutes.

- Maintain a consistent and uniform loading rate.

- Monitor Carefully:

- Observe the load application to ensure it progresses smoothly and evenly.

Post-Test Processing:

- Release Load:

- After reaching the maximum load, release the load completely and remove the assembly.

- Remove Sample:

- Carefully remove the crushed aggregate sample from the cylinder.

- Sieve the Material:

- Pass the material through a 2.36 mm IS sieve.

- Weigh Passing Material (W₂):

- Collect the fines that pass through the sieve and weigh them (W₂).

- Clean Equipment:

- Thoroughly clean all equipment for the next test.

- Document Measurements:

- Record all measurements:

- Empty cylinder weight (W)

- Filled cylinder weight (W₁)

- Weight of fines passing through 2.36 mm sieve (W₂)

- Record all measurements:

Supplementary Cementitious Materials (SCMs) are revolutionizing the way we think about construction and sustainability in the cement industry

Practical Applications and Recommendations for the Aggregate Crushing Value (ACV) Test

The primary application of the Aggregate Crushing Value (ACV) test is to assess the strength and quality of coarse aggregates for road and pavement construction, with a lower ACV indicating better strength and durability. Recommendations include performing the test on aggregates used for concrete and wearing surfaces, ensuring a result of less than 30% for concrete roads and less than 40% for wearing surfaces. For aggregates with an ACV over 30%, it is recommended to use a 10% fines value test instead.

Practical applications

- Road and pavement construction: The ACV test is crucial for selecting suitable aggregates that can withstand traffic loads and resist crushing.

- Concrete and asphalt: It helps ensure the durability and strength of concrete and asphalt by determining the aggregate’s ability to handle stress.

- Quality control: The test serves as a quality control measure before aggregates are used in construction projects to prevent structural failure.

Recommendations and standards

- For concrete roads: The aggregate crushing value should be less than 30%.

- For wearing surfaces: The aggregate crushing value should be less than 40%.

- If ACV > 30%: The 10% Fines Value test (TFV) is recommended as an alternative assessment.

- Testing procedure:

- Dry aggregates to a uniform temperature (100-110°C) before testing to account for moisture.

- Ensure the plunger in the compression testing machine rests entirely on the aggregate, without touching the cylinder walls, to prevent errors.

- Apply the load at a uniform rate to reach 40 tonnes in 10 minutes (400 kN).

- Repeat testing: The test should be repeated to ensure accuracy, and the average or median of the results should be reported.

Conclusion

The Aggregate Crushing Value (ACV) test is essential for professionals in the construction and civil engineering fields. This method provides critical insights into the strength and durability of aggregates, ensuring that they meet industry standards for various applications. By accurately assessing the crushing value, engineers can make informed decisions that contribute to the longevity of structures.