Retarders in concrete are chemical admixtures added to delay the setting time of concrete by slowing down the hydration process of cement. This allows for extended workability, making it easier to mix, transport, place, and finish concrete, especially under hot weather or complex placing conditions

Primarily, retarders slow the chemical process of hydration, ensuring that concrete remains workable even in high-temperature environments where rapid hardening is a concern. They are commonly employed in ready-mix concrete applications, large-scale pours, and specialized tasks such as oil well grouting or achieving unique surface finishes like exposed aggregates.

- Retarders are essential for improving the quality and longevity of concrete structures because they reduce the possibility of cold joints, increase workability, and allow for flexibility in placement schedules. They are a crucial part of contemporary construction methods because to their adaptability and versatility.

Mechanism of Retardation

The mechanism of retardation varies depending on the situation, but it usually entails slowing down a process by interfering with important processes.

This occurs in concrete when retarders chelate calcium ions or create a protective layer on cement particles, preventing the development of hydration products and delaying the setting and hardening process.

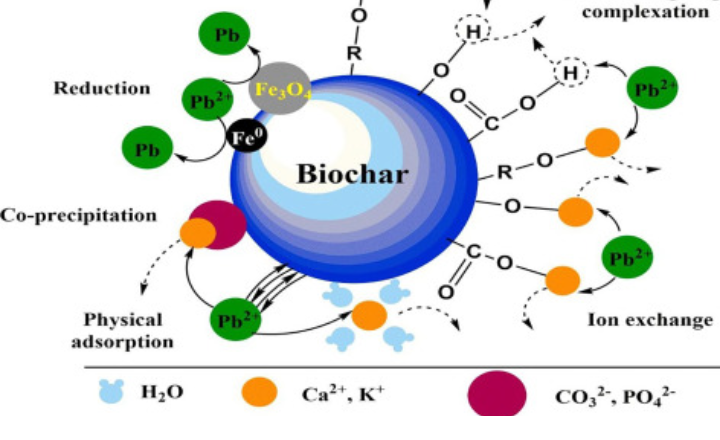

The effectiveness of retarders in concrete lies in their ability to temporarily delay the hydration process, thereby extending the setting time. This delay occurs due to various chemical and physical interactions between the retarder and the cement particles, categorized into four main mechanisms:

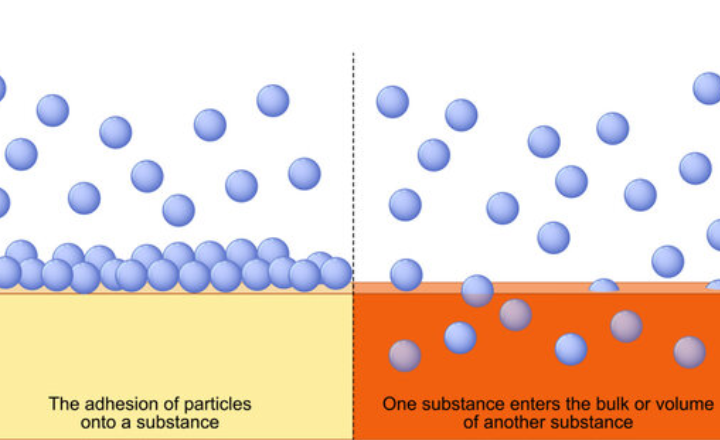

Adsorption

Retarders form a protective coating on the surfaces of cement particles, creating a physical barrier that limits water access and slows the hydration reaction. This barrier inhibits the early formation of hydration products, keeping the cement paste workable for longer.

This layer acts as a diffusion barrier, preventing water molecules from effectively reaching the unhydrated cement particles. As a result, the hydration process slows, keeping the concrete in a workable state for a longer duration.

Complexation

Retarders react with calcium ions released by the cement grains to form complexes, which increase the solubility of cement components in the aqueous phase. This accumulation of calcium and hydroxyl ions inhibits their precipitation, effectively delaying the formation of hydration products.

Precipitation

Precipitation, as a mechanism of retardation in concrete, involves the formation of insoluble derivatives of the retarder in the highly alkaline environment of the cement paste.

These insoluble compounds precipitate out and create a protective coating around the cement particles. This coating acts as a diffusion barrier that significantly slows down the penetration of water to the cement particles, thereby suppressing the hydration process.

This retardation effect delays the setting of concrete by hindering effective interaction between water and cement particles until the protective layer dissolves or breaks down over time, allowing hydration to resume

Some retarders react with the alkaline solution in the cement paste to form insoluble derivatives. These derivatives create a protective coating around the cement particles, further impeding the water-cement interaction and slowing hydration.

Temporary Nature of Retardation

Retarders in concrete show a temporary nature of retardation, meaning their effect in slowing down the hydration process is not permanent. After a certain predictable period, the hydration process resumes normally, allowing the concrete to achieve its intended strength and durability eventually.

This temporary effect occurs because the mechanisms by which retarders act, such as adsorption forming a protective layer on cement particles, inhibition of nucleation of hydration products, complexation with calcium ions, and precipitation of insoluble layers, are reversible or degrade over time

It is important to note that the retardation effects are temporary. After a predictable period, the hydration process resumes, ensuring that the concrete eventually achieves its intended strength and durability.

Types of Retarders

Retarders used in concrete can be broadly categorized into organic retarders and inorganic retarders based on their composition. Each type has unique properties that make it suitable for specific applications.

Organic Retarders

Organic retarders in concrete are chemical admixtures based on carbon compounds that delay the hydration process by various mechanisms, allowing extended workability and delayed setting times

- Lignosulphonates: Byproducts of the paper industry, these are widely used due to their dual properties of retardation and water reduction.

- Hydroxycarboxylic Acids and Their Salts: These provide consistent retardation and may enhance workability.

- Phosphonates: Known for their high efficiency in controlling hydration.

- Sugars: Simple sugars like glucose or sucrose are highly effective in small doses. Overuse, however, can lead to indefinite delays in setting.

Inorganic Retarders

Inorganic retarders in concrete are mineral salts or chemical compounds that slow down the hydration of cement primarily by interacting chemically with calcium ions and forming insoluble precipitates or complexes.

These reactions create temporary barriers that delay the setting process and reduce the rate of heat generation, especially useful in specialized or large-scale concreting operations

- Phosphonates and Borates: Often used in high-performance concretes.

- Salts of Lead (Pb), Zinc (Zn), Copper (Cu), Arsenic (As), and Antimony (Sb): These are less commonly used due to environmental concerns but can be effective in specialized applications

Combination Retarders

Combination retarders in concrete are admixtures that combine both organic and inorganic retarder compounds to achieve a balance of benefits from each type.

These admixtures take advantage of the complementary mechanisms of retardation, providing controlled, prolonged setting time and enhanced workability under various environmental and construction conditions.

Modern construction often requires admixtures that combine retardation with other benefits, such as water reduction. These hybrid admixtures, like retarding plasticizers or superplasticizers, offer enhanced performance and convenience in concrete mix designs.

Characteristics of Combination Retarders

- They provide an extended and more predictable delay in concrete setting compared to using either organic or inorganic retarders alone.

- Organic components adsorb onto cement particles and inhibit early hydration stages, while inorganic components form precipitates or complexes with calcium ions, further delaying hydration.

- This dual-action approach offers better control over setting time and heat of hydration, making it suitable for complex pours, hot weather concreting, and long-distance transportation of ready-mix concrete.

Effects of Retarders on Concrete Properties

Retarders in concrete significantly influence both fresh and hardened concrete properties, primarily by delaying the setting time and affecting hydration kinetics.

Setting Time

- Retarders are admixtures used to slow down the setting time of concrete.

- They increase both initial and final setting times, keeping concrete workable longer.

- Extra workable time helps in proper placement, compaction, and finishing.

- Ideal for large pours or complex structures where work takes more time.

- Most beneficial in hot weather, where concrete sets faster due to rapid hydration.

- Prevents premature setting and problems like cold joints and poor surface finish.

- Helps achieve better quality, strength, and durability of concrete.

Strength

- Reduced Rate of Hydration: Retarders slow down the chemical reaction between cement and water, delaying initial setting.

- Low Early Strength Gain: Because hydration starts later, the concrete shows lower compressive strength in the first few hours or days.

- Useful in Hot Weather: In high temperatures, concrete tends to set quickly. Retarders help maintain workability, even though early strength is reduced.

- Extended Workability Time: More time is available for mixing, transporting, placing, and finishing the concrete.

- Control in Large Pours: Slower setting prevents cold joints in mass concrete works, even though early strength development is delayed.

- Better Hydration Control: Slow and controlled hydration allows more complete reaction of cement particles.

- Improved Crystal Formation: Calcium silicate hydrate (C-S-H) crystals form more uniformly, contributing to improved long-term strength.

- Equal or Higher Final Strength: Properly cured retarded concrete can achieve similar or sometimes greater compressive strength than regular concrete.

- Reduced Shrinkage & Cracks: Better hydration reduces shrinkage stresses, leading to fewer cracks and improved durability.

- Enhanced Durability: Long-term properties like resistance to weathering, chemical attack, and permeability are improved.

Workability and Slump

- Retarders increase the initial slump, making concrete more workable at the start.

- They keep the mix workable for a longer time by slowing the setting process.

- Reduce slump loss, ensuring proper placement and finishing.

- Very useful for long-distance concrete transport and complex formwork.

- Help maintain workability in hot weather conditions.

Air Entrainment

- Most retarders do not change the air content in concrete.

- Some chemical retarders (e.g., hydroxycarboxylic-based) may reduce air entrainment.

- Lower air content can decrease freeze-thaw resistance in cold climates.

- Reduced air may affect workability and durability if not controlled.

- A proper mix design adjustment is needed when using such retarders.

Bleeding

- Retarded concrete stays plastic longer, which increases bleeding tendency.

- Excess water rises to the surface due to delayed setting.

- It can lead to weak surface layers and finishing issues if not controlled.

- Proper mix proportioning (lower w/c ratio, correct admixture dose) reduces bleeding.

- Good curing and timely finishing help minimize surface water accumulation.

Heat of Hydration

- Retarders do not decrease the total heat of hydration, but slow the heat-release process.

- They delay the peak temperature rise, helping control internal heat buildup.

- Useful in mass concrete works where sudden heat rise may cause cracking.

- Helps reduce thermal stresses and lowers the risk of thermal cracking.

- Provides a more uniform temperature distribution throughout the concrete section.

Durability

- With proper curing, retarded concrete develops durability equal to normal concrete.

- It can resist environmental factors like moisture, temperature changes, and chemicals.

- Controlled hydration helps form a dense and strong microstructure.

- A proper mix design ensures long-term strength and durability performance.

- Good curing practices are essential to prevent surface defects and improve resistance to weathering.

Volume Deformation

- Retarded concrete may show a slight increase in plastic shrinkage due to longer setting time.

- An extended plastic phase can allow more moisture evaporation, leading to early shrinkage.

- Creep and drying shrinkage remain mostly unchanged compared to normal concrete.

- Proper curing and moisture control can minimize plastic shrinkage effects.

- Use of fibers or surface protection can help reduce early shrinkage cracking.

Advantages of Using Retarders in Concrete

The incorporation of retarders in concrete offers several benefits that enhance its performance and usability, particularly in challenging conditions. Below are the key advantages:

Improved Workability in Hot Weather

Retarders counteract the rapid setting caused by high temperatures, allowing sufficient time for mixing, transportation, and placement.

Prevention of Cold Joints

In large or sequential pours, retarders ensure that successive layers bond seamlessly, preventing weak points or cold joints in the structure.

Enhanced Architectural Finishes

Retarders are instrumental in creating exposed aggregate finishes. By delaying surface hardening, they enable the easy removal of the cement paste, revealing aggregates for aesthetic appeal.

Versatility in Complex Placements

For intricate structures or areas with difficult access, retarders extend the working time, facilitating proper placement and compaction without compromising quality.

Compatibility with Ready-Mix Concrete

Retarders are essential in ready-mix concrete to maintain workability during long transportation times, ensuring the mix remains in a plastic state upon arrival at the site.

Temperature Control in Mass Concrete

By delaying the heat of hydration, retarders reduce the likelihood of thermal cracking in large concrete pours, promoting structural integrity.

Specialized Applications

Retarders are used in grouting deep oil wells, where high temperatures demand extended workability of the cement slurry.

Adaptability with Other Admixtures

Modern retarders often combine with plasticizers or superplasticizers, providing additional benefits like water reduction, enhanced slump retention, and improved strength development.

Applications of Retarders in Concrete

Retarders are used in various construction scenarios where controlling the setting time and maintaining workability are essential. Below are some of the key applications:

Hot Weather Concreting

In regions with high ambient temperatures, retarders slow down the hydration process, preventing rapid setting and allowing sufficient time for placement and finishing.

Ready-Mix Concrete

Retarders are crucial for maintaining workability during the transportation of ready-mix concrete over long distances, ensuring the mix remains plastic until it reaches the site.

Large-Scale Pours

In projects involving large volumes of concrete, such as dams or foundations, retarders help prevent cold joints by extending the workable time between successive pours.

Exposed Aggregate Finishes

Retarders are sprayed on formwork surfaces to delay setting at the concrete-formwork interface. This enables easy removal of the paste to expose aggregates, creating visually appealing finishes.

Slip Form Construction

In continuous construction methods like slip forming, retarders help regulate the setting time to ensure a consistent and smooth process.

Oil Well Grouting

In deep oil wells with high temperatures (up to 200°C), retarders are used in cement slurries to maintain mobility for extended periods, ensuring proper sealing and preventing gas or oil leakage.

Mass Concrete Works

Retarders are employed to manage the heat of hydration in mass concrete pours, minimizing thermal cracking and ensuring structural stability.

Decorative Concrete

For architectural projects requiring intricate designs or textures, retarders provide the flexibility to achieve desired effects without compromising the concrete’s integrity.

Selecting and Handling Retarders in Concrete

When choosing and using retarders in concrete, several factors must be considered to ensure optimal performance. The selection process involves understanding the specific requirements of the project, the type of cement, and the environmental conditions.

Type of Cement

The effectiveness of retarders can vary depending on the type of cement used. Ordinary Portland cement (OPC) typically responds well to retarders, while specialized cements like high-alumina or sulfate-resistant cements may require different retardation agents. Always match the retarder to the specific type of cement for best results.

Environmental Conditions

Hot weather is the primary condition where retarders are used, but extreme cold can also impact the effectiveness of retarders. In both cases, it is crucial to adjust the dosage of the retarder according to the temperature. Additionally, in environments with high humidity, retarders may work more effectively, while dry conditions may necessitate higher doses to achieve the same results.

Dosage and Compatibility

The amount of retarder to be added depends on the required retardation time and the temperature of the working environment. Overuse can lead to excessive delays in setting time, affecting the concrete’s strength development and workability. Always refer to manufacturer guidelines for dosage and conduct small-scale tests to determine the appropriate quantity for the job.

Monitoring and Quality Control

It’s essential to have proper inspection and control when using retarders, especially if compounds like gypsum or sugar are involved. Excessive amounts can cause undesirable expansion, delayed setting, or inconsistencies in concrete performance. Regular monitoring of the setting time and hydration process ensures that the retarder is working as intended.

Mixing and Storage

Retarders should be thoroughly mixed into the concrete to ensure even distribution. Commercial retarders often come pre-mixed with other admixtures, such as plasticizers, to maintain stability. Ensure that the retarder is stored in a cool, dry place, as exposure to extreme temperatures can degrade its effectiveness.

Potential Side Effects

While retarders are beneficial, improper use can lead to issues like excess bleeding, increased risk of cracking, or reduced early strength. Therefore, careful calculation and application are vital to ensure that the retarder enhances the concrete’s performance without causing adverse effects.

Conclusion

Retarders play a crucial role in modern concrete construction by controlling the setting time and maintaining workability under challenging conditions. From hot weather concreting to large-scale pours, these admixtures offer significant advantages by allowing more time for mixing, transporting, and placing concrete. Retarders are essential in applications like ready-mix concrete, oil well grouting, and exposed aggregate finishes, where precise control over setting times is required.

The use of retarders enhances the flexibility and efficiency of concrete, enabling it to meet the demands of diverse construction projects. Whether it’s combating the effects of high temperature or achieving specialized surface finishes, retarders are a vital tool in the concrete industry, supporting the delivery of high-quality, durable structures.