Engineering Materials

Factors Affecting Workability is a key property of fresh concrete, indicating how easily it can be mixed, placed, compacted, and finished while maintaining its homogeneity. A workable concrete mixture overcomes internal friction between particles and the frictional resistance from formwork or reinforcement with minimal compacting effort. Several factors contribute to enhancing the lubricating effect of concrete, thereby reducing internal friction and improving its ease of compaction. These factors include water content, mix proportions, aggregate size, shape, surface texture, grading, and the use of admixtures.

The Aggregate Crushing Value test (ACV)

The following are the key factors affecting the workability of concrete:

water content

Water content plays a crucial role in determining the workability of concrete, and understanding this link unveils a world of possibilities for construction professionals. Higher water content increases the fluidity of concrete, making it easier to mix, place, and compact. If additional water is necessary, the water-to-cement ratio must be maintained by adding more cement to prevent a loss of strength.

Cement Content

The workability of concrete is a crucial factor that directly influences both the quality of the final structure and the efficiency of the pouring process. One pivotal aspect is the cement content; an optimal balance can enhance fluidity and ease of placement. ultimately leading to safer and more sustainable structures.At a given water-cement (w/c) ratio, higher cement content increases the total water available in the mix, enhancing fluidity and improving consistency.

Aggregate Characteristics

Aggregate properties significantly influence the workability of concrete through their impact on surface coating requirements, friction, and mobility during mixing, placing, and compaction. The key factors affecting workability include aggregate size, aggregate-to-cement ratio, fine-to-coarse aggregate ratio, and aggregate shape and texture.

- Aggregate Size: Larger aggregates have a smaller surface area relative to their volume, requiring less cement paste for coating. This increases the amount of paste available for lubrication, improving fluidity and consistency. Conversely, smaller or finer aggregates demand more paste, potentially making the mixture less workable.

- Aggregate-to-Cement Ratio: A higher ratio implies more aggregates and less cement paste, reducing lubrication and decreasing consistency. Maintaining the right balance is crucial for achieving desirable workability.

- Fine-to-Coarse Aggregate Ratio: Increasing the fine aggregate proportion raises the total surface area, leading to higher paste demand for coating. While this may reduce consistency, it enhances cohesiveness, which can be advantageous for specific applications requiring stability.

- Shape and Texture: The shape and surface texture of aggregate particles also affect workability. Spherical, smooth aggregates reduce friction and require less paste, resulting in more workable concrete. In contrast, angular, rough, or irregular aggregates demand more paste and increase internal friction, leading to harsher mixes.

Use of Admixtures

Admixtures, both chemical and mineral, play a crucial role in enhancing the workability of concrete by influencing its fluidity, cohesiveness, and overall consistency.

Chemical Admixtures:

- Air-Entraining Agents: These increase the paste volume and improve consistency by introducing air bubbles, which act as lubricants. They also enhance cohesiveness by reducing segregation and bleeding, especially in harsh, low-cement mixtures like mass concrete.

- Water-Reducing Admixtures (Plasticizers and Superplasticizers): These improve fluidity by dispersing cement particles and releasing entrapped water. For optimal effectiveness, the initial slump of the reference mix should be around 2 to 3 cm. This ensures maximum workability improvement at a minimal dosage, maintaining cost-effectivenesMineral Admixtures:

- Fly Ash: As a partial cement replacement, fly ash improves consistency due to its spherical shape and smooth, glassy surface.

- Silica Fume: While silica fume increases cohesiveness, it can reduce fluidity due to its high surface area, which demands more water for lubrication.

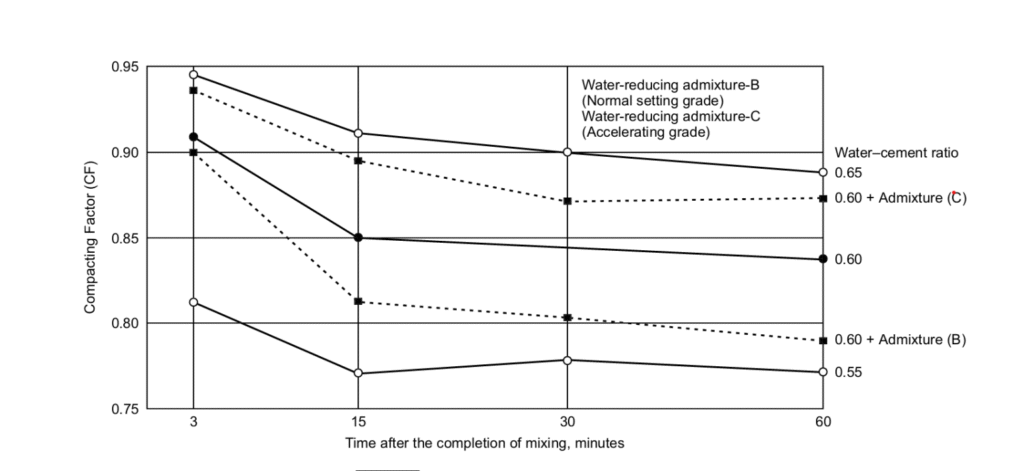

Temperature and Time

The workability of freshly mixed concrete decreases over time due to various factors, including water evaporation (accelerated by sun or wind exposure), water absorption by aggregates, and its consumption during the hydration process. This phenomenon, known as slump loss, is influenced by:

- Mix Richness: Richer mixes typically experience slower slump loss.

- Cement Type: Different types of cement have varying hydration rates, which affect workability over time.

- Temperature: Higher temperatures accelerate the hydration process and water evaporation, resulting in reduced workability and faster slump loss.

- Initial Workability: Mixtures with low initial workability are more sensitive to time-induced stiffening.

To address challenges posed by high temperatures or unusual site conditions, conducting on-site workability tests is recommended. Proper planning, including the use of water-retaining measures or admixtures, can help maintain desired workability levels under such conditions.

Mix Proportions

The aggregate-to-cement ratio significantly impacts the workability of concrete:

- Lean Concrete: A higher aggregate-to-cement ratio results in leaner concrete, where less cement paste is available for lubrication. This limits the mobility of aggregates, reducing workability.

- Rich Concrete: A lower aggregate-to-cement ratio increases the availability of cement paste, making the mix cohesive and smooth, thus enhancing workability.

Optimizing mix proportions ensures the right balance between cohesiveness and fluidity, crucial for achieving desired workability.

Grading of Aggregates

The grading of aggregates plays a critical role in influencing the workability of concrete. Well-graded aggregates, which have the least amount of voids for a given volume, require less paste for lubrication. This results in:

- Reduced Void Spaces: With fewer voids, more paste is available to lubricate the particles, improving workability.

- Enhanced Cohesion: The excess paste makes the mixture cohesive and “fatty,” helping prevent segregation of particles.

- Ease of Compaction: The better the grading, the less compacting effort is required, as the aggregate particles can slide past one another more easily.

conclusions

The workability of concrete is influenced by a number of important elements, including the moisture content, aggregate gradation, and additive use. Construction experts can optimise the mix for particular applications by knowing how these components interact. Finding the ideal balance is essential since it has a direct effect on the application procedure and the final product’s lifespan. Thus, greater performance and efficiency on-site might result from paying close attention to details during the preparation stage. For improved construction results, let’s resolve to apply these lessons to our concrete methods.