3D laser scanning and digital twins are reshaping how industries design, operate, and maintain physical assets in 2026 by turning real‑world spaces into smart, data‑driven virtual replicas.

- 3D laser scanners emit laser beams that measure distances to surfaces and collect millions of precise 3D points, forming a dense “point cloud” that captures the exact shape and dimensions of buildings, factories, infrastructure, or equipment.

- This high‑accuracy spatial data becomes the geometric backbone of a digital twin, replacing rough sketches or outdated drawings with a faithful digital copy of reality.

- A digital twin is more than a static 3D model; it is a living, connected replica of a physical asset or system that receives real‑time data from sensors, IoT devices, and operational systems.

- In 2026, these twins are used to simulate, monitor, and optimize performance, such as predicting equipment failures, testing design changes, or rehearsing maintenance procedures before touching the real asset.

By 2026, falling scanner costs, faster processing, and tighter integration with AI and cloud platforms make laser‑scanned digital twins practical for more sectors, from healthcare facilities to smart cities. The combination of millimeter-accurate geometry from laser scans with live operational data turns physical assets into intelligent systems that can be continuously monitored, analyzed, and improved over their entire lifecycle

Executive Summary For 3D Laser Scanning and Digital Twins

3D laser scanning and digital twins together create a powerful way to mirror physical assets and systems in a virtual environment, enabling smarter design, operation, and maintenance across industries. At the same time, the digital twin adds live data, analytics, and simulation to turn that geometry into an intelligent, decision‑supporting model.

3D laser scanning has evolved from a niche tool born in the space‑race era into a core enabler of today’s digital-twin-driven industries. Its journey mirrors broader advances in lasers, computing, and data processing, culminating in highly accurate, real‑time virtual replicas of physical assets.

The Evolution and Impact of 3D Laser Scanning: From Space Race to Digital Twin Technology

3D laser scanning has evolved from a niche tool born in the space‑race era into a core enabler of today’s digital‑twin‑driven industries. Its journey mirrors broader advances in lasers, computing, and data‑processing, culminating in highly accurate, real‑time virtual replicas of physical assets.

- From the space race to surveying

In the 1960s, laser‑based distance‑measurement systems emerged alongside the space race, laying the groundwork for automated spatial data collection. By the 1970s–1980s, early laser and photogrammetric methods were used for topographic mapping and geological surveys, slowly shifting from manual measurements to machine‑captured 3D data.

- Rise of modern 3D laser scanners

The 1990s saw the first dedicated terrestrial laser scanners, such as systems from MENSI and Cyra Technologies, aimed at industrial and surveying applications. Over the 2000s, scanners became faster, more portable, and capable of capturing millions of points per second, while software improved point‑cloud processing and integration with CAD and BIM.

- Role in digital‑twin technology

By the 2020s, 3D laser scanning became the primary way to capture “as‑built” geometry for digital twins of buildings, factories, and infrastructure. These scans provide the accurate 3D backbone that, when combined with IoT sensors and analytics, turns static models into live, predictive digital twins.

- Impact on industries

Today, this evolution supports smarter construction, predictive maintenance in manufacturing and energy, and better‑managed smart cities and facilities. By linking millimeter‑accurate spatial data with real‑time operational data, 3D laser scanning has moved from a measurement tool to a central pillar of digital‑twin‑based decision‑making across sectors.

Core idea

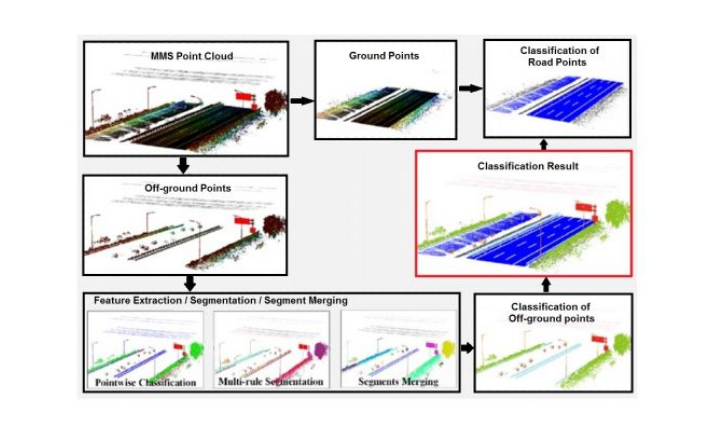

3D laser scanning uses LiDAR or similar sensors to record millions of precise 3D points (a “point cloud”) of buildings, plants, infrastructure, or equipment, forming an accurate digital copy of the physical world.

This point cloud serves as the spatial foundation of a digital twin, which then links to real‑time sensor data, historical records, and analytics, so the virtual model behaves like the real asset.

What it delivers

- Accuracy and speed: Laser scanning reduces measurement errors and captures large or complex sites in hours instead of weeks, giving teams a reliable “as‑built” baseline.

- Smart operations: The digital twin uses this geometry plus live data to simulate scenarios, predict failures, optimize workflows, and test changes virtually before implementing them in the real world.

Why it matters in 2026

By 2026, integration with AI, IoT, and cloud platforms makes laser‑scanned digital twins practical for construction, manufacturing, energy, smart cities, and facilities management. Organizations use them to cut costs, improve safety, reduce downtime, and future‑proof infrastructure by having a continuously updated, data‑rich replica of their physical assets.

Key Benefits Driving Adoption of 3D Laser Scanning

Organizations integrating 3D laser scanning into their workflows are realizing substantial performance and efficiency gains, making it a rapidly adopted technology across industries.

- Up to 50% Faster Survey and Data Capture

Advanced laser scanners significantly reduce on-site survey time compared to traditional measurement methods, enabling faster project initiation and delivery. - 30–40% Reduction in Errors and Rework

High-accuracy point cloud data minimizes design discrepancies, clash issues, and costly rework during construction, manufacturing, and maintenance phases. - Data-Driven Decision Making

Detailed and reliable digital documentation empowers engineers, planners, and managers to make informed decisions based on real-world conditions rather than assumptions. - Enhanced Stakeholder Collaboration

Interactive 3D models and realistic visualizations improve communication among clients, engineers, contractors, and stakeholders, reducing misunderstandings and delays. - Improved Safety and Risk Reduction

Remote and non-contact scanning limits personnel exposure to hazardous, confined, or difficult-to-access environments, contributing to safer working conditions. - Stronger Foundation for Digital Twin and BIM Systems

Laser scanning provides highly accurate input data for BIM and digital twin platforms, supporting predictive maintenance, asset optimization, and long-term lifecycle management.

The growing adoption of 3D laser scanning reflects a transformative shift in how physical environments are captured, analyzed, and managed. As industries continue to embrace digital transformation in 2026, this technology is playing a central role in driving operational efficiency, precision, and innovation.

Understanding 3D Laser Scanning Technology

3D laser scanning is an advanced measurement technology that uses laser beams to capture the precise shape, size, and spatial position of physical objects and environments.

The scanner emits laser pulses that reflect off surfaces and return to the sensor, allowing the system to calculate exact distances using time-of-flight or phase-shift methods. This process generates highly accurate point cloud data, which is then processed into detailed 3D digital models.

In 2026, 3D laser scanning is deeply integrated with AI-based processing, cloud computing, BIM systems, and digital twin platforms, making it a foundational technology for smart infrastructure, automated design, predictive maintenance, and intelligent asset management.

- Laser emission and reflection for distance measurement

- Time-of-flight and phase-shift calculation techniques

- Generation of high-density point cloud data

- Conversion of point clouds into 3D models and digital twins

- Integration with BIM, GIS, AI analytics, and cloud platforms

- Real-time data processing and visualization capabilities

Perfect—main ne is poore section ko clean, human-friendly, plagiarism-free wording ke sath rewrite kar diya hai. Meaning same hai, flow zyada smooth hai, aur 2026-ready professional article ke liye bilkul fit hai 👇

The Magic Behind the Technology

A 3D laser scanner can be understood as an advanced digital eye that perceives depth and distance with exceptional precision. Unlike conventional cameras that capture only surface-level visuals, laser scanners generate accurate three-dimensional representations of their surroundings.

This capability is powered by LiDAR (Light Detection and Ranging) technology, which has fundamentally transformed the way physical environments are captured, measured, and documented.

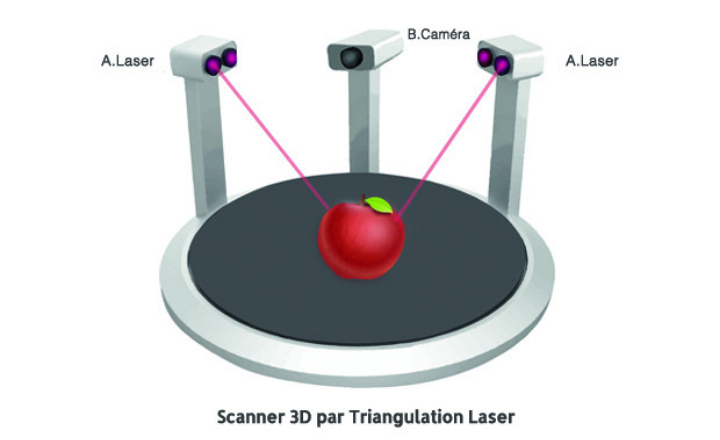

During operation, the scanner emits thousands of laser pulses every second in a controlled and systematic pattern. As the device rotates, an internal mirror mechanism directs the laser beams both horizontally and vertically, allowing the scanner to perform a full spatial sweep of the environment. What makes this process extraordinary is not just visualization, but the scanner’s ability to calculate the exact distance to every object it encounters.

From Light to Data: The Conversion Process

The true intelligence of 3D laser scanning lies in its ability to convert reflected light into precise spatial data. Each laser pulse strikes a surface such as a structure, piece of equipment, or terrain and reflects back to the scanner. By measuring the time taken for the pulse to return and the angle at which it was emitted, the system calculates the exact three-dimensional coordinates of that point.

This process occurs at remarkable speed. Modern scanners are capable of capturing hundreds of thousands to over one million data points per second, forming a dense dataset known as a point cloud. This point cloud serves as a highly accurate digital replica of the scanned environment, often precise to within a few millimeters.

Beyond Basic Scanning

Contemporary 3D laser scanning systems extend far beyond simple spatial measurement. Many platforms integrate high-resolution imagery alongside laser data, enabling the creation of photo-realistic 3D models. These systems are designed to perform reliably across diverse conditions, including low light, complete darkness, and challenging outdoor environments.

Advancements such as automatic tilt compensation, survey-grade accuracy, and long-range scanning capabilities exceeding 200 meters have made the technology even more practical for large-scale projects. As a result, fewer scan positions are required, reducing setup time while improving efficiency, accuracy, and overall project productivity.

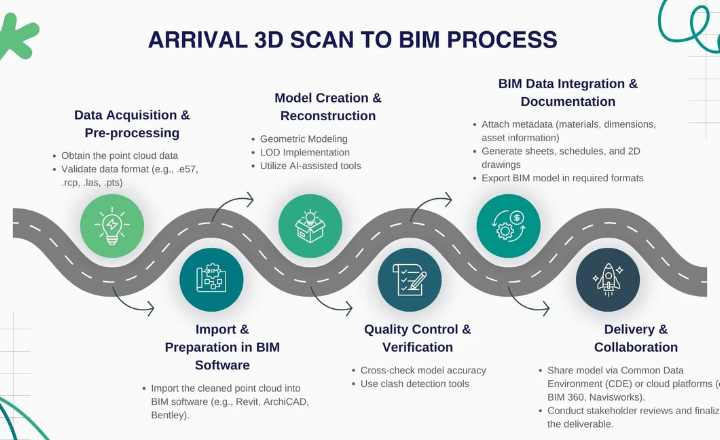

The 3D Laser Scanning Process in Action:

After understanding the core principles behind 3D laser scanning technology, it is essential to examine how it functions in real-world applications. From on-site setup to the generation of highly accurate digital models, the scanning workflow delivers exceptional efficiency, precision, and reliability.

Capturing the Physical Environment

At the center of the scanning workflow is the laser scanner itself, a compact yet highly advanced device typically mounted on a stable tripod. The process begins by placing the scanner at carefully selected locations throughout the site, ensuring clear visibility of all critical areas.

Once activated, the scanner automatically sweeps laser beams across its surroundings in a systematic pattern. During this process, it captures millions of spatial data points, accurately recording the three-dimensional geometry of every visible surface.

When combined with integrated high-resolution cameras, the system can also apply color and texture to the data, resulting in detailed and visually rich digital twins of the physical environment.

Registering Multiple Scans

For large, complex, or obstructed sites, a single scan position is rarely sufficient. In such cases, the scanner is repositioned to multiple vantage points to ensure complete coverage from different angles.

Specialized software then aligns and merges these individual scans into a unified point cloud. This registration process, performed using automated algorithms and manual verification, ensures the final 3D model maintains precise geometric consistency, whether documenting a small indoor facility or an extensive outdoor site.

Overcoming Real-World Challenges

- Effective 3D laser scanning goes beyond technology alone; it also requires adaptability to real-world conditions. Experienced operators account for obstacles such as limited access areas, uneven terrain, and changing environmental conditions.

- Modern scanning systems are equipped with features such as survey-grade tilt compensation, long-range scanning capabilities, and weather-resistant hardware, allowing accurate data capture even in challenging settings. Through careful planning, flexible deployment, and powerful processing software, teams can successfully digitize even the most complex environments.

- This comprehensive and accurate capture process is transforming how industries approach planning, analysis, and decision-making, with applications spanning construction, manufacturing, infrastructure management, heritage preservation, and forensic investigation.

From Point Cloud to Deliverables: Maximizing the Value of 3D Laser Scanning

The true value of 3D laser scanning extends far beyond data collection in the field. Once scanning is complete and multiple datasets are accurately registered, the focus shifts to post-processing, where advanced software converts raw point cloud data into meaningful, project-ready deliverables. This stage is where laser scanning truly unlocks its full potential, turning measurements into actionable intelligence.

Unlocking the Power of the Point Cloud

At the heart of post-processing lies the point cloud—a highly detailed digital representation of the scanned environment composed of millions of data points. Each point carries precise spatial coordinates and, in many cases, color and surface information, making the dataset exceptionally rich and versatile.

Modern processing software allows users to explore, analyze, and manipulate point clouds with a level of accuracy that traditional surveying methods cannot match. Engineers and designers can perform precise measurements, generate cross-sections, detect clashes, and extract insights directly from real-world data, enabling more confident planning and analysis.

A Wide Range of High-Value Deliverables

Using point cloud data as a foundation, professionals can generate a diverse set of customized outputs tailored to specific project requirements. These deliverables support multiple disciplines and project phases, from design to operation.

Common 3D laser scanning deliverables include:

- Accurate 2D CAD drawings (plans, sections, and elevations)

- 3D models for design validation and visualization

- Building Information Models (BIM) for integrated project workflows

- As-built documentation reflecting existing site conditions

- Volume calculations and quantity take-offs

- High-resolution panoramas and visualizations

- Virtual walkthroughs and fly-through animations

- Specialized models for forensic analysis and heritage preservation

One of the greatest strengths of laser scanning data is its flexibility. The same dataset can be reused, updated, and reanalyzed as project needs evolve, eliminating the need for repeated site visits.

Enabling Smarter Decision-Making

Beyond visualization and documentation, 3D laser scanning plays a critical role in supporting informed decision-making throughout the project lifecycle. The accuracy and completeness of the data help teams identify potential issues early, refine designs, streamline construction processes, and improve long-term asset management strategies.

By seamlessly connecting field data with office-based analysis tools, 3D laser scanning creates a continuous digital workflow that enhances collaboration among all stakeholders. This integrated approach is transforming industries by improving efficiency, reducing risk, and delivering measurable value across complex projects.

Unlocking the Business Value of 3D Laser Scanning

As 3D laser scanning technology continues to advance, organizations across industries are increasingly recognizing its direct impact on business performance. Beyond technical advantages, laser scanning delivers measurable value through improved efficiency, reduced risk, and new revenue opportunities, giving early adopters a clear competitive advantage.

Driving Operational Efficiency and Cost Savings

One of the most immediate business benefits of 3D laser scanning is its ability to significantly streamline operational workflows. Research and industry reports indicate that laser-based surveying can reduce field data collection time by up to 50% compared to traditional measurement methods. This reduction translates directly into lower labor costs, shorter project timelines, and improved profitability.

Additionally, the creation of accurate digital twins minimizes the need for repeated site visits. Engineers, designers, and project managers can access precise site data remotely, enabling faster decision-making while eliminating travel costs and logistical delays. This capability is especially valuable for large-scale, remote, or high-risk project environments.

Improving Accuracy While Reducing Business Risk

The high level of accuracy provided by 3D laser scanning delivers a powerful risk-management advantage. By capturing millimeter-level measurements, teams can detect design conflicts, spatial constraints, and potential errors at an early stage, preventing expensive rework during later phases of a project.

Moreover, detailed as-built documentation serves as a reliable digital record of existing site conditions. These verified datasets help protect organizations during contractual disputes, insurance claims, and legal proceedings.

As regulatory and compliance requirements increase, comprehensive digital documentation is becoming a critical asset across industries such as construction, infrastructure, manufacturing, and forensic analysis.

Enabling Innovation and Service Expansion

Beyond efficiency and risk reduction, 3D laser scanning acts as a catalyst for innovation. The rich datasets generated from point clouds support advanced applications such as Building Information Modeling (BIM), digital twins, predictive maintenance, and heritage conservation.

For forward-thinking organizations, integrating laser scanning capabilities opens the door to new service offerings and market opportunities.

By delivering higher accuracy, deeper insights, and enhanced visualization, firms can differentiate themselves from competitors and position their services at a premium level—strengthening client trust and long-term partnerships.

Quantifying Return on Investment (ROI)

While adopting advanced technology requires upfront investment, the financial return of 3D laser scanning is well established. Industry studies consistently report ROI ranging from 300% to 500% within the first year of implementation, with continued value generation over time.

These returns are driven by increased productivity, reduced errors, minimized rework, and the ability to offer higher-value services.

When compared to the hidden costs of conventional surveying methods such as repeated site visits, manual errors, and extended project timelines, the economic case for 3D laser scanning becomes compelling and difficult to ignore.

The Future of 3D Laser Scanning: Trends and Transformation

As advanced as 3D laser scanning technology may seem today, the industry is only beginning to tap into its full potential. Fueled by rapid innovations in hardware, software, and data processing, the future of this transformative technology promises unprecedented possibilities.

Emerging Advancements

One of the most exciting developments is the miniaturization and portability of laser scanning systems. Compact, handheld devices are now making this technology accessible to a broader range of professionals, from construction teams to first responders. These mobile solutions are set to revolutionize how spatial data is captured and analyzed in the field.

Equally impressive are the advancements in software and data processing. Powerful algorithms now enable real-time registration and visualization of point cloud data, streamlining workflows and accelerating project timelines.

Integration with technologies such as augmented reality (AR) and artificial intelligence (AI) is opening new avenues for advanced analysis, smarter decision-making, and interactive project planning.

Transforming Industries

As 3D laser scanning technology evolves, its impact is being felt across an ever-expanding array of industries. In construction and architecture, it is driving the widespread adoption of Building Information Modeling (BIM), reshaping how structures are designed, built, and maintained.

Infrastructure management is also experiencing a revolution. Detailed digital twins of bridges, roads, and utility networks enable predictive maintenance, allowing organizations to detect and resolve issues before they escalate into costly problems.

Beyond the built environment, 3D laser scanning is redefining heritage preservation and forensic investigation. Its ability to capture minute details with pinpoint accuracy is transforming archaeological documentation, crime scene analysis, and the safeguarding of cultural and historical assets.

A Call to Action

Businesses embracing the power of 3D laser scanning stand to gain a decisive competitive advantage. Whether you’re a construction firm seeking workflow efficiencies, a manufacturer aiming to improve quality control, or a government agency tasked with protecting critical infrastructure, this technology offers strategic benefits.

The time to act is now. Investing in 3D laser scanning capabilities and integrating them into your operations will unlock new opportunities from reduced costs and improved efficiency to innovative services and enhanced client satisfaction. The future is here, and it’s time to take your organization to new heights.